Water Soluble Fertilizer Raw Material Processing

The physical properties of water-soluble fertilizer raw materials (as particle size, humidity and content of fiber) directly affect the granulation effect. Pretreatment is necessary to eliminate differences in raw materials in order to improve the production quality of water-soluble fertilizer granules..

Raw materials are crushed. YUSHUNXIN recommends using a trituradora de fertilizantes solubles en agua. For example, The new vertical crusher or chain crusher can crush raw materials to particle size ≤3mm, ensuring that water soluble fertilizer raw materials are crushed into smaller sizes. To ensure the subsequent granulation effect.

Mix water soluble fertilizer raw materials. You can use a water soluble fertilizer mixer. Spin and mix the fertilizer raw materials inside the mixer to make them completely and evenly mixed. Thus improving the subsequent granulation effect.

Water Soluble Fertilizer Granulator Selection

The right granulator helps ensure the production of high-quality granules of water-soluble fertilizers.

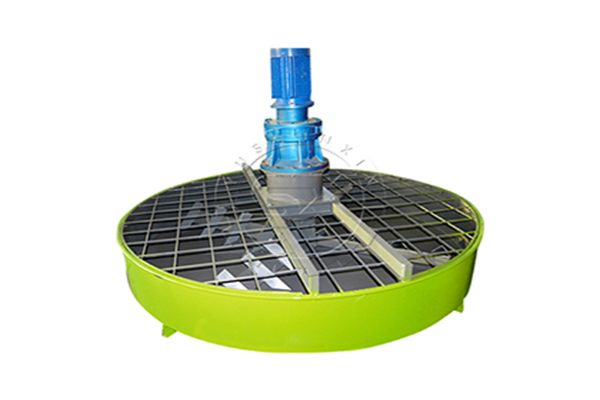

Disc granulator: Its granulation rate can reach 97%. Ball forming speed is adjusted by rotation speed (10-25 rpm). Particle size is adjusted by inclination angle (35-55°) and the diameter of the particles is adjustable from 1 a 8 mm. Suitable for small and medium production capacity.

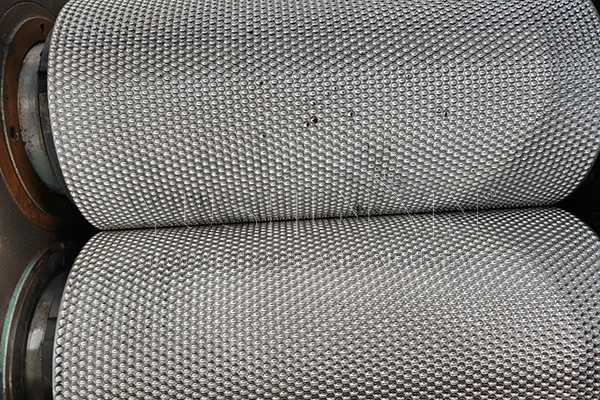

drum granulator: It has a high processing capacity (1-30t/h). Improve mixing effect through built-in lifting plate to increase particle uniformity. Combined with steam conditioning, can produce spherical particles of 3 a 6 mm. If you want a water soluble fertilizer that produces small particle size. You can choose a granulator in stock. Besides, The drum granulator is made of carbon steel outside and lined with special rubber sheets inside to prevent raw materials from sticking and has excellent corrosion resistance.

Extrusion granulator: It has strong applicability to raw materials with high fiber content, with a molding pressure of 20-50 MPa and high particle density. If you want a water soluble fertilizer that produces hard granules. It is the best choice. Besides, roller granulator adopts dry granulation technology. Produced at room temperature, no drying or cooling required, can reduce costs and increase efficiency.

Treatment of organic fertilizer after granulation

If you want to get water soluble fertilizer particles of uniform size, can use drum screening machine. It is equipped with a double-layer vibrating screen (4 meshes on the top layer and 8 tights on the bottom layer) and the screening efficiency is ≥95%. Unqualified particles are crushed and returned to the pretreatment process, and the rate of return is controlled within the 15%. To improve the production effect of water-soluble fertilizer granules.