The uniformity of water-soluble fertilizer particles is a key indicator affecting their solubility, Nutrient release efficiency and application effect. From the team perspective, YUSHUNXIN believes that the overall improvement of the uniformity of water-soluble fertilizer particles requires multi-dimensional coordination, such as raw material pretreatment, granulation process optimization and mixing system upgrades.

Raw materials pretreatment equipment.

The physical properties of water-soluble fertilizer raw materials directly affect the uniformity of granulation and should be pre-treated with the following equipment.

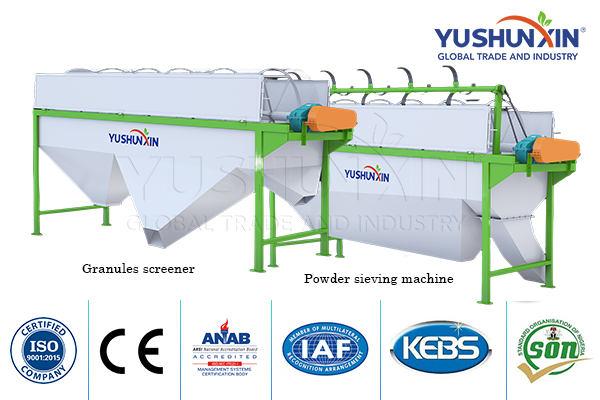

Crushing and screening equipment

Large particles or agglomerated water-soluble fertilizer raw materials will cause uneven feeding of the water soluble fertilizer granulator, and it is necessary to use integrated water-soluble fertilizer crushing and mixing equipment. The main and auxiliary materials are crushed to a uniform particle size of 2 a 5 mm and sieved through multi-layer vibrating sieve machine to prevent large particles from clogging the granulation mold.

Premix and homogenization equipment

Using an efficient mixer double axis, once launched, the load, mixing and discharging can be done uninterrupted. Can continuously produce water-soluble fertilizers. No se requiere operación manual. During the mixing process, Lumps can be removed from the inner wall of the tank to ensure that the material is completely homogenized.

Selection of granulation equipment

Different granulation processes have a significant impact on the uniformity of fertilizer granules, and it is necessary to select the appropriate equipment based on the characteristics of the water-soluble fertilizer raw materials.

Extrusion granulator

He roller granulator It is suitable for low viscosity powders, and the particle size of the water-soluble fertilizer is controlled by the opening of the matrix (as 2-4 mm) and the pressure (recommended 15-20 MPa).

Granulador de tambor

He rotary drum granulator It is suitable for large-scale water-soluble fertilizer production. Adjusting the drum inclination (5°-15°) and rotation speed (20-40 rpm), takes advantage of the centrifugal force to form uniform spherical particles. Atomizing spray device can be added to ensure uniform adhesive adhesion.

Mixing and Granulation Link System

The uniformity of water-soluble fertilizer particles not only depends on the granulation process, but also requires optimization of coordination between front and back teams.

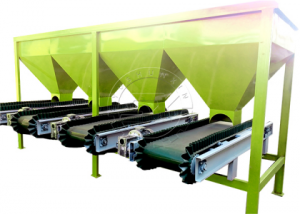

Las dynamic dispensing machines are suitable for sites with continuous dosing requirements. These sites have high requirements for continuity of dosing and, generally, do not allow interruption of intermediate dosing. The requirements for the proportion of different materials are relatively strict. Por lo tanto, dynamic dispensing machines can satisfy this requirement. The dynamic dosing system uses an electronic belt scale as measuring equipment. Main machines are equipped with alarm and PID adjustment functions, that can perform automatic control of a container (downloading materials at the same time). Avoid batch differences caused by artificial addition of materials.