Agriculture and forestry are one of the pillar industries of Chile. However, Decreased soil fertility will hinder agroforestry development. At the moment, the use of water soluble organic fertilizers can solve this problem. And the livestock industry in Chile is dominated by beef cattle breeding., sheep, pig and other animals. Therefore, liquid fertilizer production turned out to be readily available. ¿como hacer fertilizante líquido con estiercol de vaca en Chile? For example, he 23 October 2023, A customer in Chile contacted us about equipment to convert cow manure into water-soluble organic fertilizer. These are the specific details:

Main parameters

Country: Chile

Raw material: cow dung

Budget: $100,000

Equipment: liquid manure production line

how to make liquid fertilizer with cow manure?

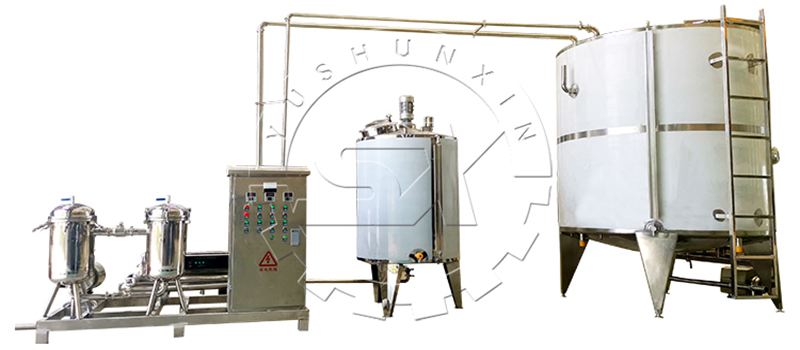

According to the requirements of the site area and production time provided by the Chilean client. We came up with a plan with a budget of 100.000 dollars. Organic fertilizer production line includes sedimentation tanks, filters, sterilizers, fermenters, 1000L finished product storage tanks and filling machines. The main function of sedimentation tank is to separate the solid-liquid in raw materials from water-soluble organic fertilizers. Filter function. Removes suspended or dissolved solid particles and impurities from liquids. Ensure the quality of raw materials of liquid organic fertilizers. La función principal del esterilizador es matar varias bacterias, virus y otros microorganismos en las materias primas de los fertilizantes líquidos. The main purpose of the fermenter is to provide a special operating environment for biochemical processes

How can I quickly separate raw materials from a water-soluble liquid fertilizer?

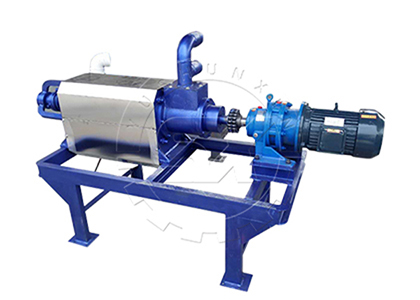

Chilean customer proposed to quickly complete the separation of water-soluble liquid fertilizer raw materials, and the liquid fertilizer production line we delivered was equipped with solid-liquid separator equipment. Compared with traditional fecal settling tanks, solid-liquid separation is faster. Besides, fecal solid-liquid separator adopts spiral extrusion principle, which can freely control the speed and water content of the discharge, and you don't need to add any flocculant. Besides, solid-liquid separator has a high degree of automation, simple operation, one person can operate, low power consumption, easy to maintain and clean.Can reduce production costs of water-soluble fertilizers.

Do you offer installation services or other technical support services?

¡Claro! With more than 80 technical engineers around the world, we can provide remote installation guidance. Of course, if you have requirements, We can also send engineers for on-site installation. In order to satisfy your needs, We will provide professional transportation and delivery services, as well as training services for installation and first-time delivery for each product. Escort your production!