Acquire appropriate equipment for production of water soluble fertilizers. It is a key step for production costs of water-soluble fertilizers.. Factors such as technical performance, Power consumption and maintainability of equipment should be fully considered during the purchasing process. Here are some specific suggestions for SX. Used to reduce production costs of water-soluble fertilizers. To help you make an informed decision when purchasing water soluble fertilizer production equipment:

Clear production requirements can reduce production costs for water-soluble fertilizers

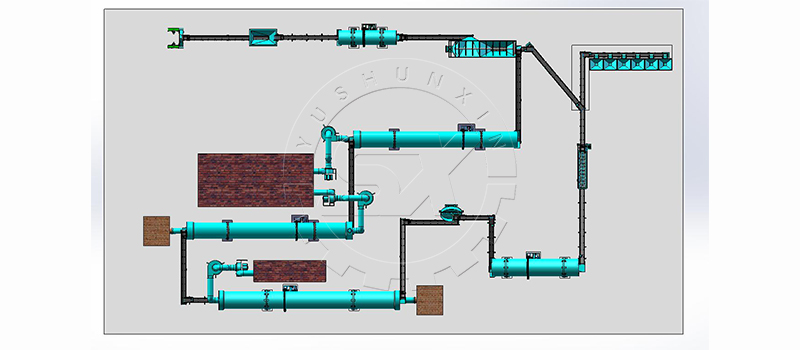

First, understand your production needs. According to your own production scale and needs. Choose water soluble fertilizer equipment with suitable production capacity. Avoid wasted resources caused by equipment that is too large or insufficient production capacity caused by equipment that is too small. Water-soluble powder fertilizer production lines are generally cheaper than granular production lines. Because the water soluble powder fertilizer production line does not require drying equipment and cooling equipment. Por tanto, the production cost of water-soluble fertilizers will be lower.

If you need to produce multiple types of water-soluble fertilizers. As water-soluble granular fertilizer. Water soluble powder fertilizer, etc. You must choose equipment with great versatility. Adapt to the production needs of different products. Besides, the production cost of liquid water-soluble fertilizer will be higher than that of solid water-soluble fertilizer. Because water-soluble liquid fertilizer production equipment must be made of stainless steel. to increase corrosion resistance and durability.

Equipment performance and technology.

In second place, consider equipment performance and technology. Look for equipment with advanced technology, which usually offer higher productivity and lower energy consumption. Using equipment with a high level of automation can reduce manual intervention, thereby reducing labor costs and human error rates.

Energy efficiency index

Then pay attention to the energy efficiency indicators of water-soluble fertilizer production equipment. Choose low energy consumption and high efficiency equipment. to reduce long-term operating costs. For example, in the selection of granulator. Disc granulators are cheaper than other granulators. Not only the granulation rate reaches the 93%. And can effectively avoid waste of raw materials, thereby reducing the production cost of water-soluble fertilizers. Besides, the production capacity of disc granulator is 1-6t/h. It can meet most production needs.In summary, he disc granulator It is an ideal and low-cost option.

Fermentation tanks can reduce production costs of water-soluble fertilizers

Finally, environmental performance. Choose equipment that meets environmental standards to reduce the cost of waste disposal and environmental compliance. For example, when choosing composting equipment, fermentation tanks are more environmentally friendly than others composting equipment. Debido a que el tanque de fermentación adopta una fermentación cerrada, does not cause contamination to the process. Besides, the fermentation tank occupies the smallest area, which can reduce the waste of land resources, thus further reducing the production costs of water-soluble fertilizers.