In the process of producción de fertilizantes orgánicos solubles en agua, material return is a common problem. The materials returned in the production process of water-soluble fertilizers not only affect production efficiency., but also causes waste of resources. To solve this problem, YUSHUNXIN recommends the chain crusher. This article will explore the suitability of chain mills for regrind processing., their feed and discharge particle sizes, the types of engines used and their productivity.

Is the chain pulverizer suitable for return material processing?

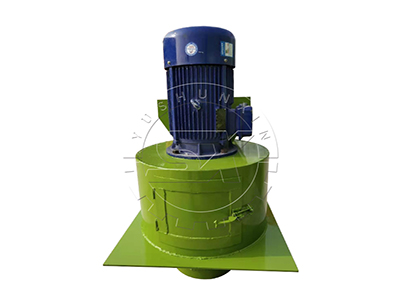

¡Sí! Chain crusher is a kind of equipment specially used to crush the returned materials in the production process of water-soluble fertilizers. It is suitable for processing various types of materials, including return materials in the production of organic fertilizers. Single and double rotor design makes it very suitable for processing return materials. Can quickly crush return material particles to required specifications, thus facilitating further processing.

Besides, the trituradora de fertilizantes soluble en agua It also has strong resistance to wear and corrosion, which is very important for processing organic return materials containing high humidity and corrosive substances.

What is the feed and discharge particle size of chain crusher?

The feed particle size of the chain crusher used for processing the returned materials in the production process of water-soluble fertilizers is generally required to be less than 40 mm. This means you can manage returns from most production processes. The particle size of the chain crusher is usually between 1 y 5 mm, depending on equipment model and specific production requirements.

What motor does the chain crusher use??

Chain shredders generally use electric motors as energy source. The power of these motors varies depending on the equipment model and production capacity., generally ranging between 18.5kW and 75kW. The motor has good starting performance and high efficiency, and can maintain stable performance during long-term high load operation. Besides, compared to internal combustion engines, electric motors are quieter during operation, They have lower maintenance costs and are more environmentally friendly.

What is the productivity of chain crusher?

The productivity of a chain sprayer depends on many factors, including equipment type, the nature of raw materials and operating conditions. In general terms, The processing capacity of small chain crushers is 1 a 5 tons/hour, while the processing capacity of large equipment can reach 10 a 20 tons/hour.