The rapid production of water-soluble fertilizer pellets requires a combination of advanced production technology and scientific management methods to ensure efficiency., The high quality and economy of water-soluble fertilizer products.

Is there any tips to quickly make water soluble fertilizer pellets?

Of course! If you want to quickly produce water-soluble granular fertilizer, You can use the process dry granulation, that does not require drying or cooling steps. Dry granulation is a granulation method that does not use a liquid binder during the granulation process.. In this method, water-soluble powder fertilizer raw materials are mixed evenly, They are compressed into flakes or plates and then crushed and granulated to produce water-soluble fertilizer particles of the required size.

Which granulators are suitable for dry granulation processes?

For dry granulation, you can choose double roller extrusion granulator or flat die granulator.

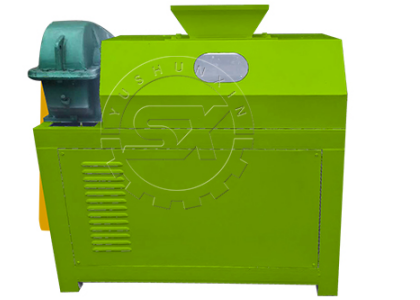

Double Roller Extrusion Granulator

The principle of operation of the double roller extrusion granulator is to compress dry materials into large, hard pieces (cake materials) under pressure, and then the cake materials are crushed and sieved to become granular materials. The double roller extrusion granulator has flexible process arrangements and can be used with one or several granulators at the same time.. Solve the disadvantages of complex processes, large investments in equipment and inconsistent quality of finished products produced by multiple teams.

Flat Die Granulator

Working principle of flat die granulator is to compress and deform solid materials under pressure through the flat die device in the main machine, thus forming granular water-soluble fertilizer products. The flat die granulator YUSHUNX It adopts an enlarged pressure wheel and corresponding enlarged bearings to improve its ability to withstand pressure. and covers an area of less than 3 m.

How much does a dry granulator cost??

The price of the dry granulator depends on the model, ability, material and specific technical parameters of the equipment. The price of SX roller granulator is between 3600 y 6500 USD. Equipment models include three specifications: SXDG-1T, SXDG-1.5T y SXDG-2T. For example, The power of SXDG-1.5T roller granulator is 18,5 kW and its price is 5100 USD. Can meet your different production needs. Besides, The price of a flat die pellet mill varies between $4.500 y $12.000. Production can reach 1 a 2,5 t/h. There are three models: SXPM-400, SXPM-500 y SXPM-600. Flat die pellet machine like SXPM-500. Cuesta $7.800. The power is 37kw.

Is there any tips to quickly make water soluble organic fertilizer pellets?

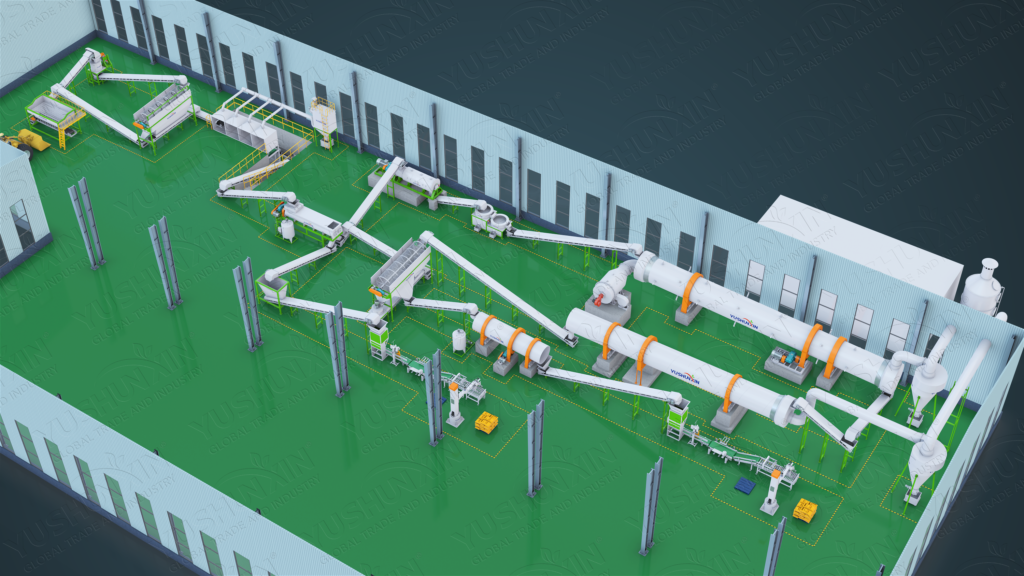

If you want to quickly granulate water soluble organic fertilizer, he composting equipment You can choose a fermentation tank for fermentation in the composting stage. Porque el tanque de fermentación adopta una fermentación cerrada. Large amounts of oxygen can be produced during fermentation. Thus promoting cell growth and metabolism. Besides, The fermentation tank is equipped with a temperature control system. Temperature can be monitored and adjusted in real time. Ensure that the fermentation process takes place within a suitable temperature range. Thus accelerating the production of water-soluble fertilizers. The production process can also use automated production lines to reduce manual intervention and improve production efficiency.. In second place, reduce the production cost of water soluble fertilizers.

If animal manure is used to produce water-soluble organic fertilizer. A solid-liquid separator can be used instead of a settling tank. He solid-liquid separator is a piece of equipment specially used for dry and wet separation of animal manure. Solid-liquid separation is very fast. The moisture content of the separated feces residue is between 50% y el 60%. Moisture content can be adjusted. Suitable for animal manure of different compositions. Besides, our solid-liquid separators have strong decontamination capabilities, They are easy to clean and do not clog.

What are the features of SX solid-liquid separator?

Our manure dewatering machines can quickly separate wet and dry animal manure. And the separated dry feces are almost odorless. It can also be used as raw material for fish feed., planting and production of various fertilizers.

- Practicality: This series of dewatering separators can quickly separate solids from liquids. After being dehydrated by this machine, The water content is approximately 30%. Therefore, It is convenient for transportation or as raw material for the production of organic fertilizers.

- High efficiency: Our dehydrator has a great capacity to remove stains, Does not clog and is easy to clean. Solids content removal efficiency, chemical oxygen demand, total oxygen demand, ammonia and phosphorus in the treated feces and urine mixture may vary between 70 y el 95%.

- Durable: the frame, The sieve and other important parts are made of stainless steel and treated with anti-corrosion. In particular, we use stainless steel 304 for parts that come into contact with the material. Therefore, It has good corrosion resistance and sufficient strength for long service life.