elaboracion de fertilizantes organicos solubles en agua

Application: Manufacturing of water-soluble organic fertilizers.

Products: powder fertilizer, granulated fertilizer, liquid fertilizer

Material: carbon steel and stainless steel

Raw materials: animal manure, organic waste, humic acids, amino acids, molasses, etc.

Description

Water-soluble organic fertilizers are divided into water-soluble solid organic fertilizers and water soluble liquid organic fertilizers. Water-soluble solid organic fertilizer is divided into water soluble organic powder fertilizer y water soluble granular organic fertilizer. There are different water soluble organic fertilizer production equipment for different water soluble organic fertilizer products.

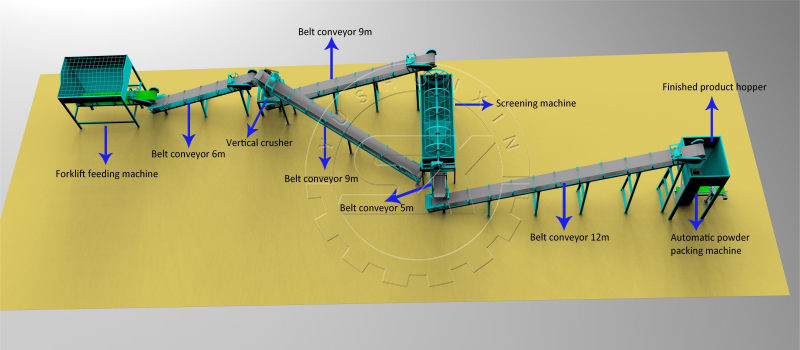

What equipment is needed to produce water soluble organic fertilizer powder?

The equipment needed for water-soluble organic powder fertilizer mainly includes composters, dosing machines, crushers, sieving machines, packaging machines, etc. Water-soluble powder fertilizer production equipment is connected by conveyor belts and dust-free cloths, and the variables are controlled by a central control system.

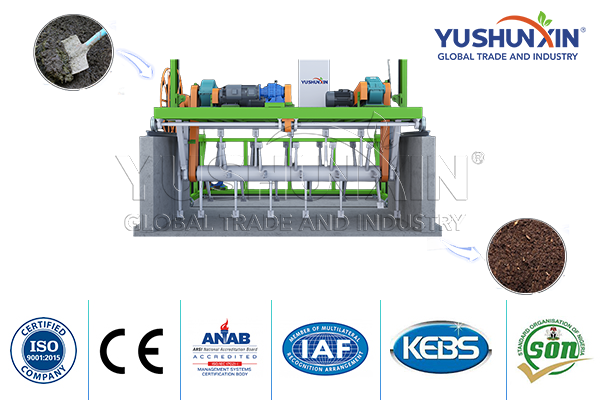

composting machine

A composter is a machine that is used to promote the fermentation process of organic waste to convert it into fertilizer.. He composting equipment of water-soluble organic fertilizers includes trough type, caterpillar type and fermentation tank.

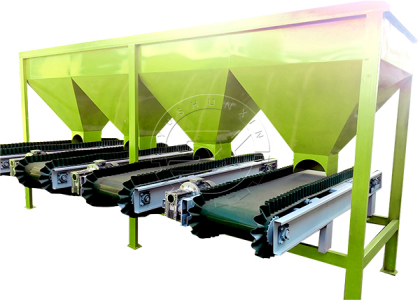

Feeder

Our feeders include forklift feeders, static dispensers and dynamic automatic dosing systems. If you want a conveyor with fine materials with a particle size of less than 5 mm, and can also transport large materials with a size of more than 1 cm, you can choose a forklift feeder. If you want a dynamic or static dispenser, you can choose static dispenser and dynamic automatic dosing system.

Crushing equipment

The crusher crushes raw materials into smaller, easier to handle powders. Facilitate the processing and use in the production of water-soluble organic fertilizers. Our crushers include new vertical crushers and chain crushers. If your material has a high moisture content, you can choose a new vertical crusher. If you use it to shred materials returned in production, you can choose a chain crusher.

Mixer

Mixers are used to mix different materials and fertilizers, and its purpose is to guarantee a uniform distribution of nutrients in the fertilizer. Mixers used in the production of water-soluble organic fertilizers include horizontal mixers and disc mixers.. If you need a high-performance blender, you can choose a horizontal mixer. If you need one that takes up little space, opt for a disc mixer.

screening machine

The sieving machine removes impurities and large particles from the fertilizer through the sieve to ensure the purity of the water-soluble organic fertilizer.

packaging machine

Our packaging machines are divided into single bucket automatic packaging scales and double bucket automatic packaging scales. If it is an elaboration of small scale water soluble organic fertilizers, you can choose single bucket automatic packaging scale. If it is an elaboration of large scale water soluble organic fertilizers, you can choose two bucket automatic packaging scale.

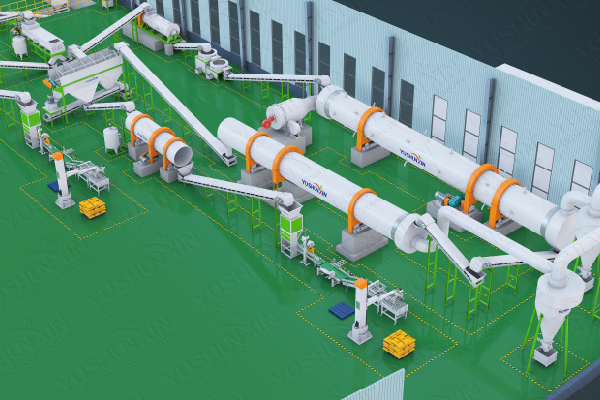

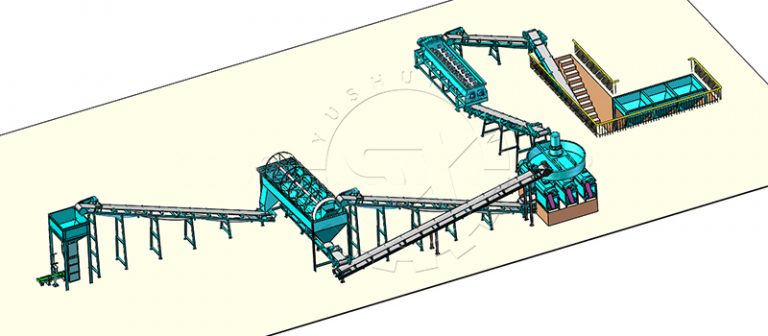

What equipment exists for the production of water soluble organic fertilizer granulation production line?

The production of water-soluble granular organic fertilizer is based on composters, dosing machines, crushers and mixers. Also requires granulators, dryers and coolers, screening machines and packaging machines.

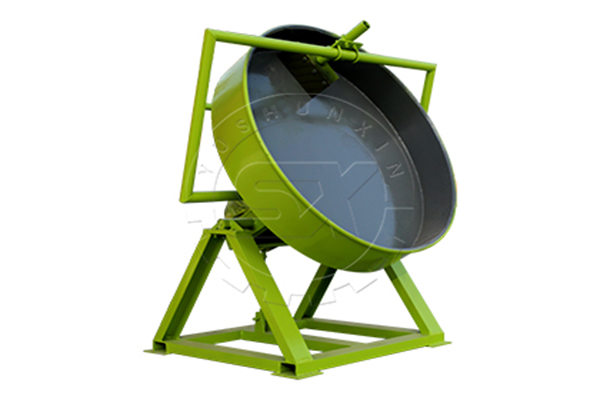

Granulator

He granulator It is the key equipment in the production of water-soluble organic fertilizers. It is the equipment to manufacture granules in the production of fertilizers. You can alter the handling properties, fertilizer transportation and storage. If you produce water-soluble organic fertilizers in large quantities, you can choose a drum granulator. If you want a low cost, you can choose a disc granulator.

Dryer

He drum dryer can heat the fertilizer evenly during the drying process and quickly remove moisture, thereby reducing the moisture content of the fertilizer to less than 10%, greatly improving the storage stability of fertilizer and extending its shelf life.

packaging machine

Our packaging machines are divided into single-bucket automatic packaging scales and double-bucket automatic packaging scales..

What equipment is needed for the production of organic liquid fertilizer?

The equipment necessary for the production of water-soluble liquid organic fertilizers includes filters, sterilizers, reactors and filling machines.

Filter

The filter can effectively remove suspended solids, organic matter, heavy metals and other impurities in organic liquid fertilizers to ensure the purity of water-soluble organic fertilizers.

Sterilizer

In the production process of water-soluble liquid organic fertilizer, the sterilizer plays a key role. It is mainly used to kill harmful bacteria or inhibit the growth of microorganisms to ensure product safety and stability..

Reactor

In the production process of water-soluble liquid fertilizers, the reactor plays a key role. The reactor is used to evenly mix various fertilizer raw materials, additives and water to ensure that the composition ratio of water-soluble liquid fertilizer is constant. A commonly used chelating agent is acid etilendiaminotetraacético (EDTA).

filling machine

The filling machine is an automated production equipment, which is generally used to fill materials in different shapes, as water-soluble liquid organic fertilizers, in containers of various specifications. According to the requirements of different water-soluble liquid organic fertilizer products, water-soluble liquid organic fertilizer is poured into the container according to a certain proportion and weight.

What raw materials can be used to produce water-soluble organic fertilizers?

Raw materials for producing water-soluble organic fertilizers include:

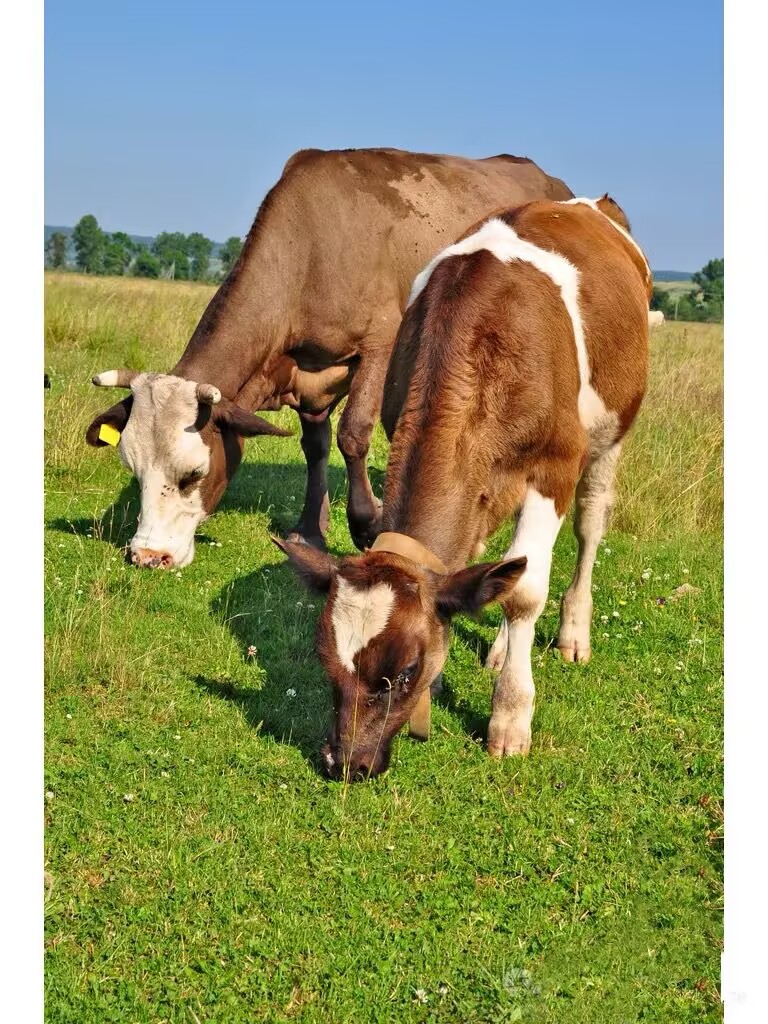

- Livestock and poultry manure: like chicken manure, beef dung, sheep and horse, estiércol de cerdo, etc. Por lo general, These feces must be completely broken down and fermented to eliminate harmful substances such as bacteria and insect eggs that may be present.

- Industrial waste: like distillers grains, vinegar granules, cassava waste, sugar waste, etc.

- agricultural waste: straw (like corn straw, wheat straw), soy flour, cotton flour, bacterial waste, biogas waste, bacterial waste, etc.

- Domestic garbage and municipal garbage: like food scraps, river sludge, sewage sludge, etc.

- Other biomass raw materials: like bran, rice husk, rapeseed cake, bean cake, torta de maní, sunflower seed oil, cottonseed cake, tea seed cake, etc., crowd, etc.

How much does an organic fertilizer production line cost?

- The price of an organic fertilizer powder production line is between 35.000 y 90.000 dollars.

- The price of a granular organic fertilizer production line is approximately between 110.000 y 550.000 dollars.

- The price of an organic liquid fertilizer production line is between 30.000 y 200.000 dollars.