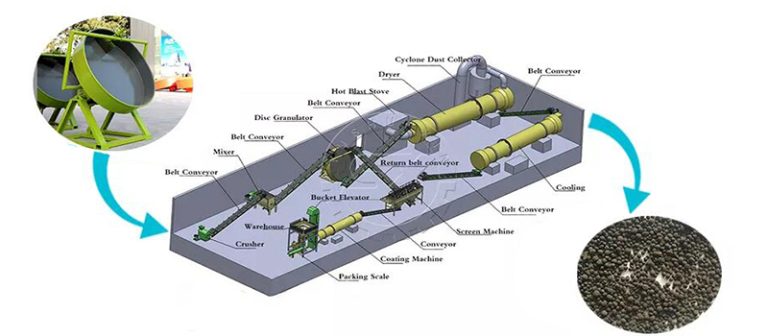

18 March 2025. We received an email from a client in Ecuador. He told us that he wanted to buy an NPK fertilizer preparation line. Produce water-soluble fertilizers with NPK and trace elements. The production is 5 t/h. Specific details are as follows:

Can the disc granulator adopt closed design?

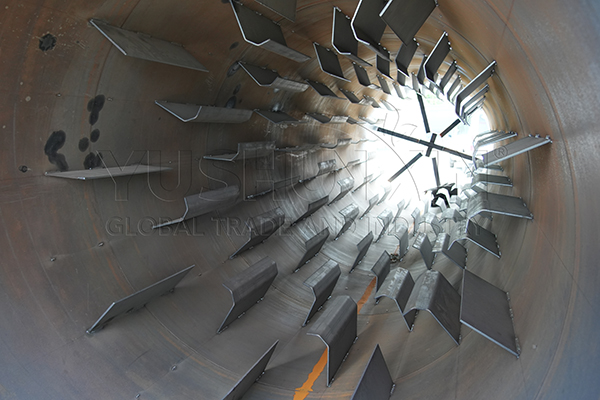

We told this Ecuadorian client that the disc granulator could be a closed design. The closed design can better control the quality of NPK water-soluble fertilizer particles and control the generation of dust.. The granulating part can be covered with an iron cover to prevent dust generation..

What material is the stock dryer made of?

The material of the strand dryer is acero carbono Q235, which has high strength and is not easy to deform. Besides, drum dryers can be heated directly or indirectly. During direct heating, the heating gas comes into direct contact with the NPK water-soluble fertilizer, while during indirect heating, the heating gas contacts the NPK water-soluble fertilizer through a heat exchanger to complete the drying of the water-soluble fertilizer.

How to pay for 5t/h NPK fertilizer preparation line?

The payment terms of YUSHUNXIN They are a deposit of 50% by bank transfer and the balance must be paid before the delivery of the NPK fertilizer production line 5 t/h. During installation, Our engineers will guide the installation and commissioning of the machine on site until it works normally and train your workers how to operate the production line and how to do simple daily maintenance. You only have to pay the round trip plane ticket, 100$ daily salary and accommodation.

What is the productivity of a 5t/h NPK fertilizer assembly line??

This NPK fertilizer production line of 5 t/h has a productivity of 100% (that is to say, no waste is generated during operation). The tray granulator, conveyor belts and sieves are covered so that no dust remains suspended in the air. Dust removal system materials can be recycled again. Reduce material waste.