He 15 January 2025, a client of Green Plains for Pilot Projects LLC consulted YUSHUNXIN about installing NPK liquid fertilizer production line for your investor in Oman. The line requires a production of 1000 tons per hour (t/h), using urea powder, phosphoric acid and potassium nitrate (KNO₃).What equipment is used? Is there an automatic system? How is the temperature adjusted in the chelation process?? Next, the specific aspects of the negotiation are detailed:

Project summary

- Location: Oman

- Ability: 1000 L/H

- Material: urea, phosphoric acid and potassium nitrate (KNO₃)

- Requirements: Preparation of NPK liquid fertilizers

What is the design of a NPK liquid fertilizer production line? 1000 t/h in Oman?

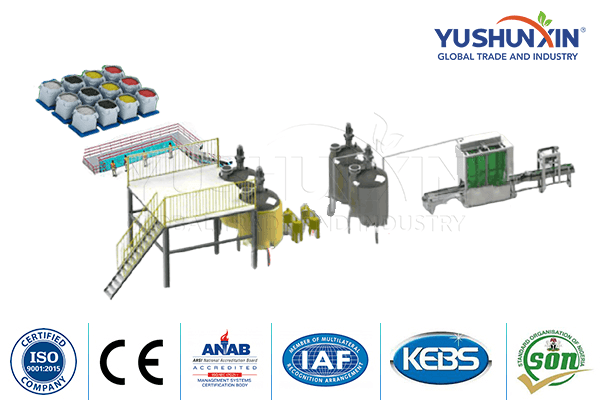

The NPK liquid fertilizer production line with a capacity of 1000 t/h usually includes several key sections: a dynamic dispenser, liquid chelation tanks 1000 L, impurity filters, storage tanks and an automatic filling system.

- The dynamic doser precisely doses each raw material to maintain the required nutrient proportions..

- Next, in liquid chelation tanks 1000 L, the chemical materials are dissolved and the reaction occurs.

- After chelation, impurity filters remove solid waste, ensuring the production of a clear and uniform NPK liquid fertilizer.

- The purified product flows to storage tanks, where it remains ready for packaging.

- Finally, filling system transfers fertilizer to bottles, drums or containers for sale or application in the field.

Each section is connected by corrosion resistant pipes, and the system design is designed to facilitate maintenance and optimize energy efficiency.

Do you offer automatic liquid filling machines?

For him NPK liquid fertilizer packaging, A customer from Oman requested an automatic system. Is it possible?

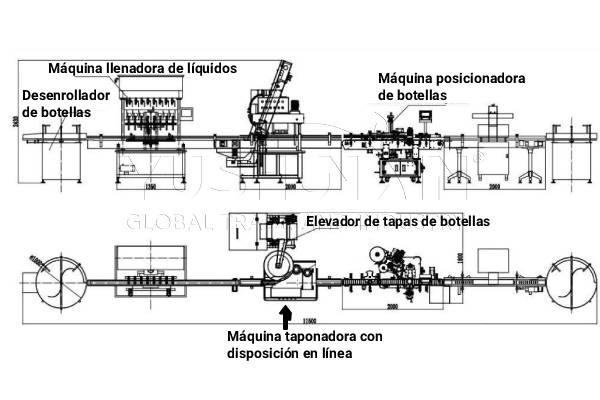

Of course, We can offer automatic liquid filling machine as part of NPK liquid fertilizer production line. Automatic NPK Liquid Fertilizer Packaging System Includes Filling, capped and labeled, inter alia. You can choose to use components or the complete system. Besides, thanks to the PLC control system, works without human intervention once configured.

Considering the rapid production of commercial NPK liquid fertilizer, The customer in Oman chose to purchase a complete automatic liquid fertilizer packaging system from 5 a 20 L.

How to adjust the chelation temperature of NPK liquid fertilizer?

Oman NPK Liquid Fertilizer Manufacturer Focused on Chelation Temperature. Can we keep it at 80℃?

Yeah. YUSHUNXIN designs chelation tanks for liquid fertilizer with mixing and heating systems. Besides, The entire process is controlled by an electrical cabinet. Of course, can adjust the temperature of NPK liquid fertilizer reactor to 80℃. This is optimal to ensure effective dissolution of nutrients from the liquid fertilizer..

Is it possible to produce liquid NPK fertilizer from powder materials?

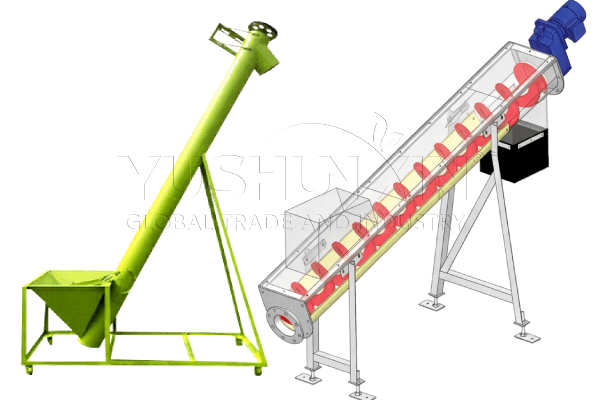

The client from Oman wanted to know in detail the process of transporting NPK powder materials to the liquid fertilizer reactor.

When preparing liquid NPK fertilizer from urea, phosphoric acid and potassium nitrate (KNO₃) powdered, It is recommended to use a combination of dynamic feeder and screw conveyors before chelation. The dispenser allows precise and fast feeding of N powders, P and K in the required proportion. Later, The screw conveyor transports the powder mixture to the liquid fertilizer reactor tank precisely and without generating dust.

Is a single screw conveyor enough? Generally, as in the case of liquid NPK fertilizer manufacturers in Oman, no auxiliary material required for the dosing tank; one is enough. This is because there is a conveyor belt below the dynamic feeder that transfers all the main materials to the screw conveyor.. For the production of liquid NPK fertilizer with auxiliary material, it may be necessary to add an additional conveyor to transport it to the dosing tank.

How to know how much liquid NPK fertilizer is left in the storage tanks?

Here we offer you two types of storage tanks for finished liquid fertilizers: stainless steel and white. White tanks make it easy to see the amount of fertilizer remaining. This transparency avoids waste and confusion when emptying or refilling the tank.

The above details our communication with the client regarding the installation of a NPK liquid fertilizer production line in Oman. Contact us to learn more about our NPK liquid fertilizer production plan. Besides, we also offer soluble NPK powder fertilizer production lines, NPK soluble fertilizer granulation plants, etc.