19 January 2025. We received an email from a client in Guatemala. Plan to build a compound granular fertilizer production line. Raw materials are phosphoric acid, urea y sal de potasio, with a performance of 4 t/h. The particle size of the compound fertilizer to be produced must be 8 mm. Specific details are as follows:

What equipment does the production line of granular fertilizers composed of 4 t/h?

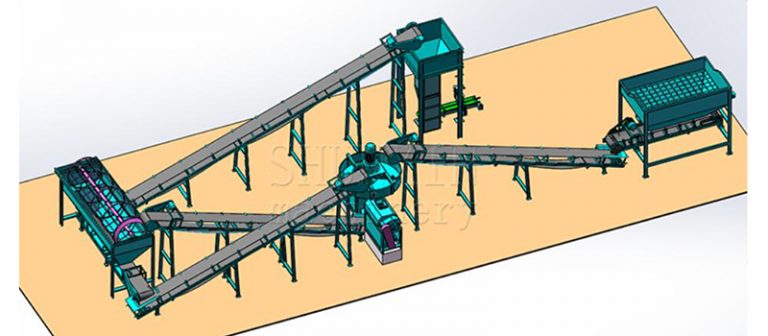

Según el requerimiento de capacidad de producción de 4 t/h provided by customer. YUSHUNXIN equipped this production line with a static automatic dosing machine, a urea crusher, a SWJ-9015 horizontal mixer, two double roller extrusion granulators and one single bucket packaging machine.

What is the working principle of double roller extrusion granulator?

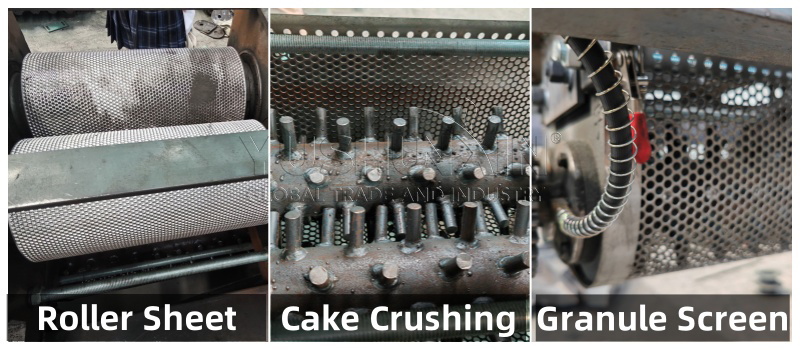

He granulador de extrusión de doble rodillo It is the core equipment of compound fertilizer production line and its working principle is physical extrusion molding technology. Two parallel and counter-rotating rollers are used to force the pretreated raw materials (mixed phosphoric acid powder, urea y sal de potasio) inside the concave mold on the surface of the roller. under high pressure (generally 20-50 MPa), the dust is compressed into dense flakes, which are then broken into granules using a scraper.

What size fertilizer does the roller granulator produce??

The customer told us that he wanted to produce granular fertilizer composed of 8 mm. We told you that the particle size of the water-soluble fertilizer produced by the roller granulator is usually between 3 mm y 10 mm. Can meet your production needs. Besides, The roller head is the key factor to change the size and shape of the particles, and there are many options. We can provide pillow-shaped nests, semicircular, stick, pill, nutty, oblate spherical and square stick. Para tu elección.

How many people are needed for a granular compound fertilizer production line? 4 t/h?

This granular fertilizer production line composed of 4 t/h only requires 3 personas. Hay 2 people in charge of pretreatment and feeding of raw materials (responsible for weighing and mixing phosphoric acid, la urea y la sal de potasio). Supervision of the granulation section: 1 persona (granulator operating parameters). The packaging stage uses a fully automatic control system (Integrated PLC) and does not require manual supervision.