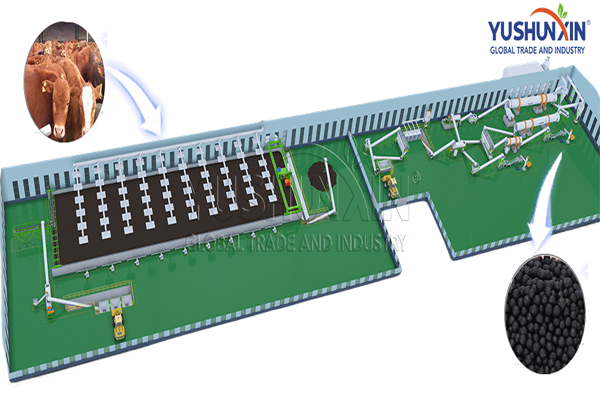

cow dung as water soluble fertilizer

Ingredients: cow dung

Product: Gránulos

Application: water soluble organic fertilizer

Material: carbon steel

Teams: Composting, feeding, trituration, mix, granulation, drying and screening, packing.

Description

Cow dung water soluble fertilizer is a liquid fertilizer made by fermenting cow dung and water.How can cow dung be used as a water soluble fertilizer.The equipment for produce water-soluble organic fertilizers from cow dung include composting equipment, feeding equipment and crushing equipment. Equipos de mezcla, equipos de granulación, drying and screening equipment, equipos de envasado, etc.

What production equipment is needed to produce water-soluble granular fertilizer from cow dung?

Composting equipment

The use of compost equipment can speed up the fermentation process. Composting equipment for using cow dung as water soluble fertilizer can be chosen using trough composters, mobile composters and fermentation tanks.

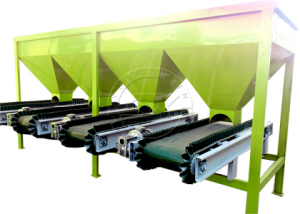

Feeding equipment

Dispensing equipment includes forklift feeding machines, static dosing machines and dynamic automatic dosing systems. If you want to transport fine materials with a particle size less than 5 mm and large materials with a size larger than 1 cm, you can opt for a forklift feeder. Whether you want a dynamic or static dispensing machine, You can choose between a static dispensing machine and a dynamic automatic dispensing system.

Crushing equipment

He equipo de trituración to use cow dung as water-soluble fertilizer may include new vertical crushers and semi-wet material crushers. For materials with higher moisture content, you can choose a new vertical crusher.

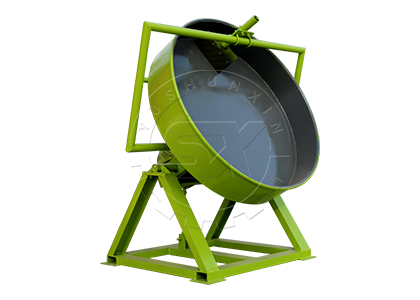

Equipo de mezcla

The mixing equipment used in Yushun cow dung water soluble fertilizer includes horizontal mixer and disc mixer. For large-scale production of water-soluble fertilizer with cow dung, you can opt for a horizontal mixer. If the site is limited, puede elegir un mezclador de discos. It has the advantage of taking up little space.

The drying and screening equipment used for cow dung water soluble fertilizer includes secadora de tambor and drum screening machine.

Equipo de granulación

He fertilizer granulator cow dung water soluble can choose disc granulator and flat die granulator. If you want a water soluble fertilizer with exquisite particles, a flat die granulator can meet your needs. If you want a cheap one, and disc granulator can meet your needs.

Packaging equipment

He equipo de envasado used in the production of water soluble fertilizers from cow dung includes automatic single bucket packaging scales (doble). Snap producing water-soluble organic fertilizers on a smaller scale, you can choose single bucket automatic packaging machine. Snap producing water-soluble organic fertilizers on a larger scale, puede elegir una máquina de envasado automática de dos baldes.

What is the production process of cow manure as liquid fertilizer ?

- Collection and preprocessing of raw materials: Collect fresh cow manure and reduce its moisture content through a dehydrator to facilitate further processing. If required, Appropriate amounts of auxiliary materials can be added (like straw, sawdust, etc.) to adjust the humidity and ratio carbon-nitrogen.

- Fermentation and decomposition: evenly mix the pretreated cow manure and microbial fermentation agent and stack them in the fermentation tank. Use a composter to turn the pile regularly to ensure the materials are completely fermented and decomposed.

- Crushing and screening: The fermented and decomposed materials are crushed through a semi-wet material crusher to obtain a fine powder with uniform particle size.. Use drum screening machine to screen the crushed materials and remove impurities and unqualified particles.

- Dosing and mixing: According to production needs, the sieved fine powder is mixed with auxiliary materials such as trace elements and humic acid. Use a horizontal mixer or a disc blender to mix the ingredients well..

- Granulación: use equipment such as a disc granulator or a new organic fertilizer granulator to granulate the mixed materials. By adjusting the parameters of the granulator, granulated organic fertilizer that meets the requirements is obtained..

- Drying and cooling: Send the granulated particles to a drum dryer to dry and remove excess moisture.

- packaging: use automatic packaging machine to quantitatively package qualified particles for easy storage and transportation.