NPK Granular Fertilizer Production Line

Product: Granulated

Precio: $110,000-$550,000

Surface: 2000-10000 square meters

Raw materials: Nitrogen, Phosphorus and Potassium

Application: Compound fertilizer production line.

Description

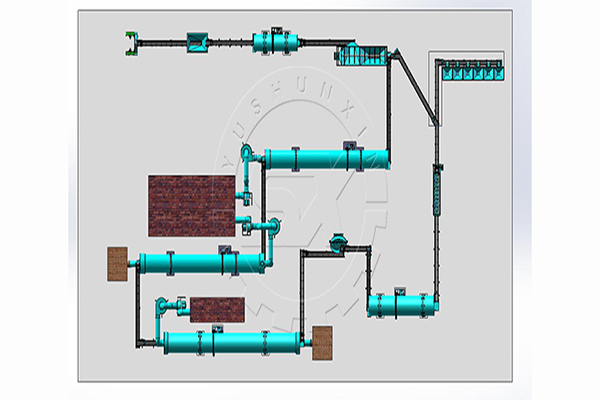

The production of NPK granular fertilizers generally includes several steps, as preparation of raw material, mix, granulation, drying and packaging. Choosing the right granulation equipment is crucial to producing high quality NPK granular fertilizer.

Besides, granular npk fertilizer production line 1-20t/h. The price is approx. $110.000-$550.000. Production lines with different outputs are equipped with different equipment. If you also have NPK granular fertilizer production needs, contact us. We have a professional team of engineers to customize production solutions for you!!

How to produce NPK granular fertilizers?

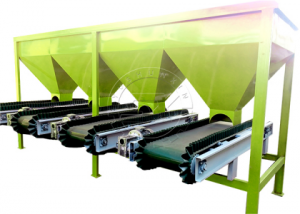

NPK raw material preparation

To produce NPK fertilizer it is necessary to prepare a nitrogen source, a source of phosphorus and a source of potassium. Como la urea, he diammonium phosphate, he potassium chloride, etc. To ensure uniform distribution of nitrogen nutrients (N), match (P) and potassium (K) in NPK granular fertilizer. We recommend that you use an automatic dosing system when preparing ingredients. It has a multi-container design and can precisely control the discharge amount. To ensure that each nutrient element can be precisely dosed. If it is a small scale production, a static dosing system can be used. If you are producing granular NPK fertilizer on a large scale, can use a dynamic dosing system.

NPK raw material mix

To mix different raw materials evenly and ensure the uniformity of NPK fertilizer composition, you can use a water soluble fertilizer mixer. Drive the stirring shaft through the motor to rotate, mixing the npk raw materials of the fertilizer inside the mixer. Thus achieving a uniform mixing effect.

Granulación de fertilizante NPK

So that the NPK fertilizer is less likely to agglomerate during storage and has good flowability. You have to granulate. For this purpose, you can use a granulator. Nuestros 3 models of water soluble fertilizer granulators best sellers are the disc granulator, drum granulator and roller extrusion granulator.

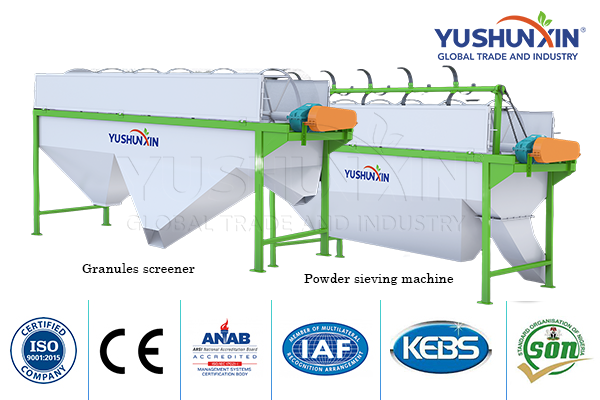

NPK particle screening

To produce granular NPK fertilizer of uniform size. It is recommended to use a drum screening machine. It is equipped with an electric vibrating screen to filter out unqualified particles (too big or too small).

It is widely used for screening various solids below 300 mm. Its screening capacity has reached 20t/h.

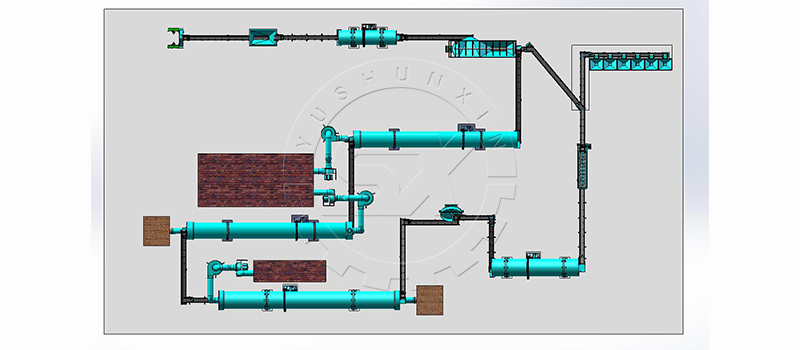

Drying and cooling of NPK granules

Drying can reduce the moisture in NPK fertilizer and improve the hardness of NPK fertilizer granules. Reduces breakage and dust formation during transport and application. We recommend using a dryer. Drum dryers can be heated directly or indirectly.

In direct heating, the heating gas is in direct contact with the NPK fertilizer. During indirect heating, The heated gas contacts the water-soluble fertilizer through a heat exchanger to complete the drying of the granular NPK fertilizer..

Besides, the performance of drum dryer varies between 1 y 18 t/h. It can meet your different NPK fertilizer drying needs.. Qualified NPK particles must be cooled to avoid agglomeration. For this you can use a drum cooler.

NPK granular fertilizer containers

To facilitate subsequent transportation and sale. NPK granular fertilizer must be packaged. We recommend using a packaging machine automatic. It has a double bucket packaging scale and a single bucket packaging scale.. Besides, la precisión cuantitativa del sistema es del 0,2%. Can meet your different packaging needs. Like for example 10 kg, 20 kg, 50 kg, etc.

If you are a small scale NPK fertilizer producer, You can choose a single bucket automatic packaging scale. Its operation and maintenance are relatively simple and performance is usually of 5 t/h. If you are producing on a large scale, you can choose double bucket automatic packaging scale. Has two sets of independent measuring hoppers, which greatly improves packaging speed, and production is generally 5 a 10 t/h.

Los 3 best selling NPK fertilizer granulators

I want to produce NPK granular fertilizer. Choosing the right pelletizer is important. Granulator is a key equipment in fertilizer production line, which can improve handling performance, fertilizer transportation and storage. YUSHUNXIN recommends the disc granulator, drum granulator and roller granulator.

Cost effective disc granulator

The price of the disc granulator is between $3000 y $7000. Compared with other NPK granular fertilizer granulators, the price is lower. The production is 1 a 6 t/h. If you want a low price pellet machine. Disc granulator can be selected. He granulation disc of the disc granulator adopts arc structure as a whole and the granulation rate can be as high as more than 93%.

Besides, The disc granulator is equipped with a scraper to prevent material from sticking and accumulating in the disc granulator, thereby reducing material waste. If you have energy saving and environmental protection needs, we can also meet your needs. The disc granulator has low noise and does not produce dust pollution during operation, which meets the ecological and environmental protection requirements of modern industrial production.

Granulador de tambor de 30 t/h

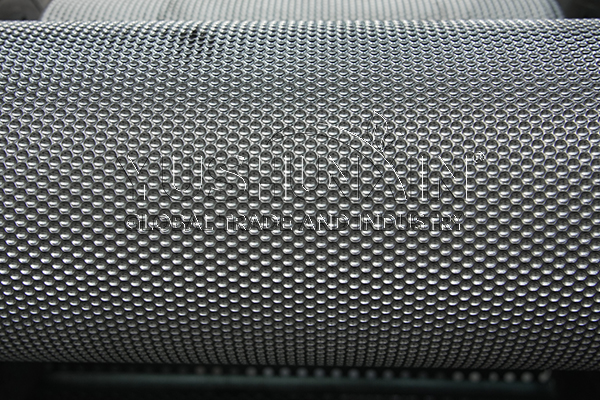

The maximum output of drum granulator can reach 30 t/h. Besides, drum granulator uses rubber engineering plastics as liner, which prevents raw materials from sticking to the drum and plays an anti-corrosion function. If you want a machine with strong anti-corrosion ability and great performance, you can choose drum granulator.

The working principle of granulador de tambor is to mix the basic fertilizer powder and send it to the drum granulator, and use the friction and extrusion force generated by the rotating movement of the drum to agglomerate the material particles to form water-soluble fertilizer particles of a specific shape.

Non-drying roller granulator

If you do not want to purchase drying equipment. You can choose roller granulator. It adopts dry granulation process and is formed in one step without drying or cooling. The production is 1-3t/h. The particle size range of NPK fertilizer produced by the roller granulator It is usually between 3 mm y 10 mm. Can meet your production needs of different sizes.

Besides, is flexibly organized in the process and can be used simultaneously with one or several granulators, thus solving the inconveniences of the complex process, the large investment in equipment and the inconsistent quality of finished products produced by multiple devices.

What is the price of NPK granular fertilizer production line?

The cost of building an NPK fertilizer production line will be affected by many factors., including line scale, the degree of automation, team selection, geographic location and specific production processes.

NPK Granular Fertilizer Production Line Price 1 a 5 t/h

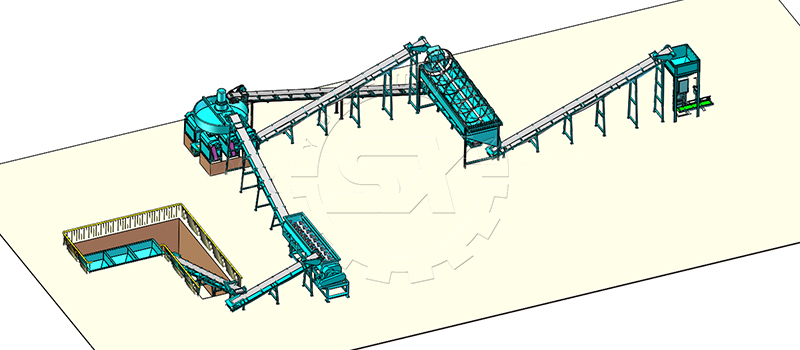

Línea de producción de fertilizantes granulados npk a pequeña escala. The price is around 110.000-190.000 dollars. The equipment you need to use includes a static dispenser, an SXPJ-1800 disc mixer, 2 roller granulators, a rotary drum dryer and cooler, a drum screen, a single bucket canner and 4 conveyor belts. This NPK water soluble fertilizer production line covers an area of 2000 a 4500 square meters.

NPK Granular Fertilizer Production Line Price 5 a 10 t/h

Línea de producción de fertilizante granulado npk de 5-10 t/h. The price is estimated between 190.000 y 360.000 dollars. This production line is equipped with 2 static dispensers, single and double shaft mixers, 2 disc granulators, drum sieving machine, simple and bucket packaging machine 6 conveyor belts. The site area you need to prepare for this NPK fertilizer production line is 4500 a 5500 square meters.

NPK Granular Fertilizer Production Line Price 10 a 20 t/h

If it is large-scale NPK granular fertilizer production. You can choose this line. This production line modernized small-scale production line equipment. The price is approx. $360.000-$550.000.

This production line is equipped with a dynamic dosing system, a horizontal mixer, un granulador de tambor, a drum drying and cooling machine, a drum screening machine, a double bucket packaging machine and 4 conveyor belts. For this, It is necessary to prepare an area of land 5.500 a 10.000 square meters.

How to make slow release npk granular fertilizer?

Slow release npk granular fertilizer production can be processed using coating machine. Drum coating machine is widely used in NPK granular fertilizer after cooling and before fertilizer packaging.

Use powder or liquid coating technology to form a protective film on the surface of granular fertilizers, which can effectively prevent fertilizer particles from agglomerating and nutrient loss, making the particles brighter.

Besides, Our model of rotary drum coating machine is designed with various capacities of rotary coating equipment. From 1t/h hasta 30t/h for your choice. Whether you want to start a small NPK granular fertilizer production, medium or large scale. Completely meet your different production needs.

How to start the production of NPK granular fertilizers in Bolivia?

Bolivia is an important agricultural country and the demand for water-soluble fertilizers has had an upward trend. Therefore, Investing in the construction of an NPK fertilizer plant is a good option. Below are some of the offers in Bolivia:

12 May 2024 Clients from Bolivia asked us how to start the production of NPK granular fertilizer. 5 t/h in Bolivia. The client told us that he wanted to produce granular NPK fertilizer from urea, ammonium sulfate, diammonium phosphate, fluorinated potassium phosphorus sulfate.

The Bolivian client told us that they plan to produce 5 tons of NPK fertilizer per hour. For this we have proposed a production line solution. According to this production capacity requirement, We have equipped this NPK granular fertilizer production line with automatic dosing machine, urea crusher, double shaft mixer, SXJZ-1200 drum granulator, dryer, máquina de cribado, dosing packaging machine and other auxiliary equipment to produce NPK granular fertilizers.

If you are also interested in the production of water-soluble organic fertilizers y la water soluble liquid NPK fertilizer production. Don't hesitate to send us questions!