Water Soluble Fertilizer Dosing Machine

Description

Water soluble fertilizer metering machine is essential equipment for producing high quality fertilizers. For this, SX can provide you four types of dispensing machines for your choice. They have forklift feeders, static dosing machines and automatic dynamic dosing equipment. It can fully satisfy customers' requirements for different fertilizer preparations.. If you want more details, contact us now!

Las 4 best water soluble fertilizer dosing machine

Alimentador de montacargas

If only one raw material is used to produce water-soluble fertilizer. So, forklift feeder is your best choice. It consists of a feeding silo and an electronic belt scale. It has the advantages of low power consumption, less leaks, long life and easy maintenance.

Besides, Forklift feeder is also a transportation equipment for bulk materials. It can transport both fine materials with particle size less than 5 mm as bulk materials greater than 1 cm. At the same time, It is widely used in agriculture, construction materials, chemical industry, metallurgy and other work departments.

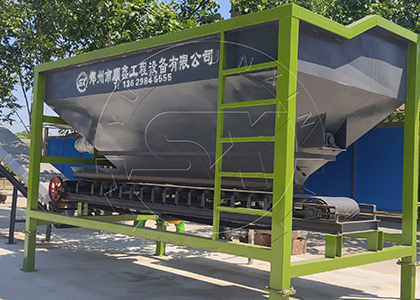

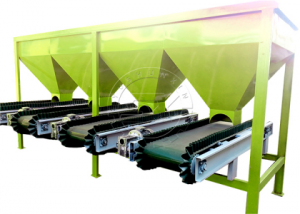

Static dosing system

When a variety of raw materials are used to produce water-soluble fertilizers. We will recommend a static dosing system. Static dosing equipment is used in fertilizer production when raw materials need to be quantitatively dosed.. The machine is mainly composed of a feeding system, a scale, a silo and a conveyor belt. Features a high degree of automation and only requires manual feeding.

If you like reduce the cost of water and fertilizer production, it's perfect for you. Because it has a high degree of automation, can save you labor costs. It is controlled by a program to weigh, Automatically mix and transport various raw materials to designated locations according to a preset formula.

Automatic dynamic dosing system

If you are producing water soluble fertilizers on a large scale. Then you can choose a dynamic dosing machine. Dynamic dispensing machines are suitable for sites with continuous dispensing requirements, as fertilizer dosage, coking dosage, etc. These sites have high requirements for continuity of dosing and, generally, do not allow interruption of intermediate dosing. The requirements for the proportion of different materials are relatively strict.

Therefore, dynamic dispensing machines can satisfy this requirement. The dynamic dosing system uses an electronic belt scale as measuring equipment. Main machines are equipped with alarm and setting functions PID, that can perform automatic control of a container (downloading materials at the same time).

Dosing tank

If you use it for production of water-soluble liquid fertilizers, you can choose a dosing tank. Our dosing tank is made of double-layer stainless steel and has strong corrosion resistance.

In the production of liquid fertilizers, liquid raw materials have certain acidity and alkalinity. Stainless steel dosing tanks can resist corrosion from these chemicals, which extends the useful life of the equipment. Reduce your maintenance and replacement costs. Besides, tiene función de agitación en su interior. Can meet your raw material mixing needs.

What is the discharge accuracy of water soluble fertilizer metering machine?

The discharge accuracy of our water soluble fertilizer metering machine is 0,2%. Accuracy is mainly controlled by some operations:

First of all, YUSHUNXIN static machine uses split type weighing sensor, which has strong anti-interference ability. The dynamic machine is equipped with a double screw feeder to avoid bridging.

In second place, The inner wall of the batching machine silo is sprayed with Teflon coating to reduce sticking and waste of raw materials.

Finally, uses a PID adaptive algorithm to adjust the feeding speed in real time based on the fluidity of raw materials. After producing each batch, A “zero calibration” is automatically performed to eliminate accumulated errors.

Can the dosing machine transport raw materials with high viscosity?

safe! For forklift feeders, Its hopper is equipped with a hydraulic arc breaker arm to forcefully break up agglomerated materials. Reduce adhesion. The static dosing machine is equipped with a high-frequency pneumatic vibrator (The frequency can be adjusted to 2000 times/minute) in the silo to prevent the material from sticking to the wall. The dynamic metering machine improves the pushing force by changing the spiral conveying section to a double-axis dragon structure.. To avoid getting caught.

Can water soluble fertilizer metering machine be used with production line?

The answer is yes! The water soluble fertilizer dosing machine can be seamlessly integrated with the production line. The dispensing machine should be placed at the front end of the water soluble fertilizer production line to provide raw materials for further production.

The height difference between the discharge port of the dosing machine and the downstream production line equipment should be≤1,5metros, to prevent excessive falling material from causing damage from dust or particles. The most commonly used dispensing machine production lines include dispensing machines, mixers, granuladoras, dryers and packaging machines.

If you are also interested in other water soluble fertilizer equipment, as water soluble fertilizer crusher, mezcladora de fertilizantes solubles en agua, granuladora de fertilizantes solubles en agua, etc. You can contact us at any time to get detailed information about the equipment!!