soluble fertilizer crusher machine

Ability: 1-20 T/H

Grinding rate: 99%

Crushing size: 0,3-5 mm

Equipment material: carbon steel

Application: Organic fertilizer, compound fertilizer.

Applicable raw materials: organic waste and inorganic matter.

Description

The water soluble fertilizer crusher machine is used to crush raw materials into smaller, easy-to-handle powders for easy processing and use in the production of water-soluble organic fertilizers., water-soluble compound fertilizers and rock phosphate fertilizers.

What are the suitable crushers for the production of water-soluble organic fertilizers??

For the production of water-soluble organic fertilizers, you can choose new vertical crushers, straw crushing machine and semi-wet material crushers.

New vertical crusher

For materials with high moisture content, you can choose new vertical crushers. The feed size of the new vertical crusher is 0,4-0,65 mm and the maximum production can reach 15 t/h. The new vertical crusher uses a high-speed rotating casing to collide with the material, and the material is turned into powder by extrusion and multiple collisions. Our new crusher vertical has great adaptability to materials with high moisture content, It is not easy to block and feeds smoothly. The shredder blade is made of special material and has a service life that is more than three times that of similar products.

Semi-wet material crusher

The semi-wet material crushing machine has a particle size of 50 mm and a production capacity of 1-8 t/h. The semi-wet material crusher machine uses high-speed rotating blades to cut and crush the materials.. When the engine starts, drives the rotor to rotate and the blades cut and shred the materials. Due to the coordination between the stator and the rotor, the crushing chamber forms a closed space, so the materials collide, they rub and cut constantly under the action of the rotor, and finally crushed into fine particles.

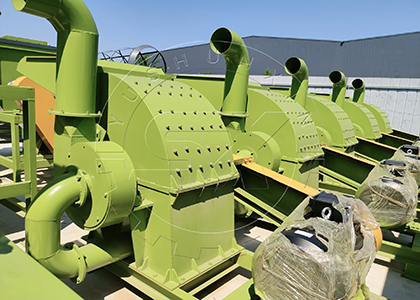

straw crusher

For crushing auxiliary materials, you can choose a straw crusher. The straw crusher uses high-speed rotating blades or hammers to impact crop residues such as straw into the crushing chamber., so that eddy currents are formed between the high-speed rotating blades or hammers and the inner wall of the crushing chamber, and finally crushed into fine particles. The straw crusher occupies a small area, It is easy to pack and simple to operate, and has no dust contamination. It is an ideal equipment to manufacture powder to produce water soluble fertilizers.

What are the suitable crushing machines for the production of compound fertilizers??

Cage crushers can be selected, chain crushers and urea crushing machine for water soluble compound fertilizer production.

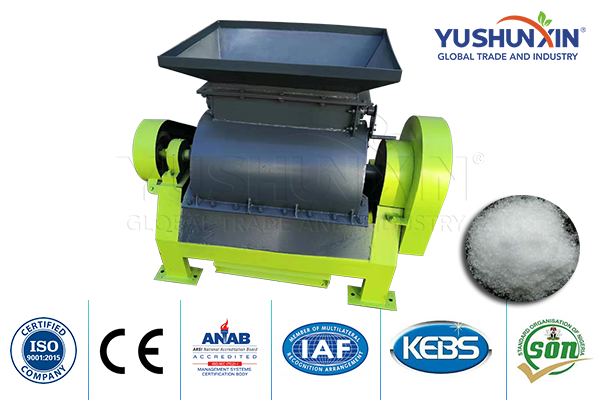

urea crusher

The feeding size of urea crusher should be ≤4mm and the discharge size should be 0,3-0,5 mm. The urea crusher has two rollers that rotate relatively, one is a fixed roller and the other is a moving roller. The urea raw material enters the space between the two rollers and is crushed under the extrusion of the rollers. By adjusting the gap between the two rollers, can control the particle size of crushed urea. The smaller the space, the finer the particle size will be after grinding; the larger the space, the coarser the particle size will be. The urea crusher screen can sieve the crushed urea particles and the crushed particle size is uniform.

cage crusher

If you want a smaller download size, you can choose the cage crusher. Cage crusher particle discharge size is ≤0.3mm. The cage crusher is a medium size horizontal cage bar crusher. The machine is designed according to the crushing principle by impact. The inner and outer groups of cage bars rotate in opposite directions at high speed. The material is crushed from the inside to the outside by the impact of the cage bars. It is a powerful tool for crushing compound fertilizers. The cage crusher has the characteristics of simple structure and high crushing efficiency, and is suitable for crushing various granular materials. And the sealing performance is good, which reduces dust leakage.

chain crusher

If you want to use it to crush return material in the production of water-soluble fertilizers, you can choose a chain crusher. Chain crusher feed particle size should be ≤100-150mm, and the output can be as high as 15t / h. The chain crusher impacts and collides the material through the high-speed rotating chain, thus crushing the material. The main working part of the chain crusher is a rotor with a steel chain, the end of the chain is connected to the rotor and the other end is equipped with a chain head made of wear-resistant steel. The chain crusher makes the material impact on the block through the high-speed rotating chain to crush it. The chain crusher is suitable for crushing blocks in the production of compound fertilizers and for recovering materials in the production of water-soluble fertilizers.

What are the suitable crushing machines for the production of phosphate fertilizers??

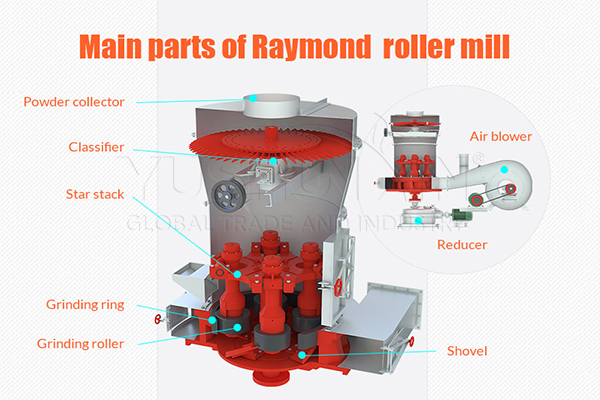

For the phosphate fertilizer production, can choose Raymond mill. The Raymond mill can crush the phosphate rock.

The working principle of the Raymond mill is that the material to be crushed is added to the machine from the feeding hopper on the side of the machine cover., and the grinding roller device suspended on the plum blossom frame of the main machine rotates around the vertical axis and rotates at the same time. Due to centrifugal force during rotation, the grinding roller swings outward and presses against the grinding ring, so that the scraper picks up the material and sends it between the grinding roller and grinding ring. The purpose of crushing the material is achieved due to the rolling and crushing of the grinding roller.

What is the price of water soluble fertilizer crusher?

The price of SX crushing equipment depends on the type, equipment configuration and materials.

The price of a crusher used in the production of water-soluble organic fertilizers varies between US$3,000 and US$12,000. For example, A new SXLFL-600 vertical crusher costs around $3.000. Semi-wet material sprayers like the SXSF-90 cost around $51.000.

The price of the crusher used in the production of water-soluble compound fertilizers varies between US$ 3.200 y US$ 9.000. For example, The price of SXLTF-800 chain crusher is $9000 and the price of SXLSF-800 cage crusher is $6000.

The price of Raymond mill used in the production of phosphate fertilizers is 18.000 US dollars.

If your water soluble fertilizer manufacturing business needs a crusher, contact us today!