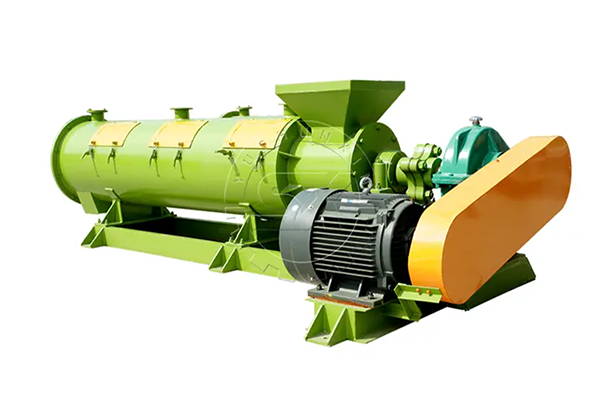

New organic fertilizer granulator

Material: Alloy

Power: 37-110kW

Granulation rate: 97%

particle size: 2-5 mm

Particle hardness: 5-8 Mohs

Production: 1-8 tons/hour

Applicable raw materials: livestock and poultry manure, residuos orgánicos urbanos, sludge, etc.

Description

The granulator is a key equipment in the process of production of water-soluble organic fertilizers. The new type of organic fertilizer granulator is made of wear-resistant alloy steel as the main material. Applicable raw materials include livestock and poultry manure, crop straw, humic acid, residuos orgánicos urbanos, sludge, etc. Besides, Its production capacity is 1 a 8 t/h, which is suitable for the needs of different water-soluble fertilizer production lines. The size of the output particles is 2-5 mm.

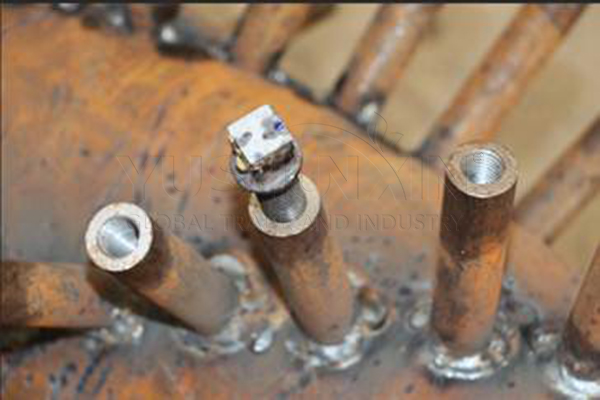

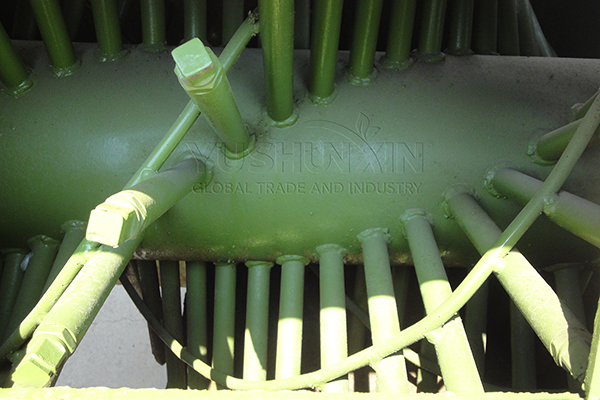

What material is the new organic fertilizer granulator made of??

The new organic fertilizer granulation machine generally adopts stainless steel High quality and wear-resistant alloy steel as main material. These materials can ensure the corrosion resistance and service life of the equipment and are suitable for long-term operation in different acidic and alkaline environments.. Compared with traditional materials, The use of stainless steel and alloy steel not only increases the durability of the equipment, but also reduces the frequency of maintenance and parts replacement. Besides, some key components may use ceramic coatings or other special materials to further improve wear resistance and corrosion protection.

What raw materials are suitable for the new organic fertilizer granulator?

The New Organic Fertilizer Granulation Machine is suitable for a variety of organic raw materials, which include, among others, livestock and poultry manure, crop straw, humic acid, desechos orgánicos urbanos, sludge, etc. These raw materials are first fermented to remove most of the moisture and pathogenic microorganisms., and then sent to the granulator for further processing. He water soluble fertilizer granulator can completely granulate raw materials into uniform and stable water-soluble granular fertilizers.

What is the production capacity of the new organic fertilizer granulator?

The production capacity of new organic fertilizer granulators varies depending on the specific model and design. In general terms, small equipment production is 1 a 4 t/h per hour, while the production of large-scale industrial new organic fertilizer granulation equipment can reach 4 a 8 t/h per hour. For example, the production of New Organic Fertilizer Granulation Machine SXJZ-800 is 1,5 a 2,5 t/h, and the production of New Organic Fertilizer Granulation Machine SXJZ-1500 is 6 a 8 t/h.

Main parameters:

| Model | SXJZ-600 | SXJZ-800 | SXJZ-1000 | SXJZ-1200 | SXJZ-1500 |

| Installation angle(°) | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 | 2-2.5 |

| Power total (kw) | 37 | 55 | 75 | 90 | 110 |

| Food moisture | 20%-40% | 20%-40% | 20%-40% | 20%-40% | 20%-40% |

| Food size(mesh) | 50 | 50 | 50 | 50 | 50 |

| Production capacity | 1-1.5 | 1.5-2.5 | 2-4 | 4-6 | 6-8 |

| Dimensions(mm) | 4100*1600*1150 | 4250*1850*1300 | 4700*2350*1600 | 4900*2550*1800 | 5500*2800*2000 |

What is the size of water soluble fertilizer particles produced by the new organic fertilizer granulator?

The new organic fertilizer granulator is capable of producing water-soluble fertilizer granules with a diameter varying between 2 y 5 mm. This size is considered the best balance point, which can ensure both the dissolution rate of granules and the stable release of nutrients. Besides, The new organic fertilizer granulator can adjust the granulation parameters to produce water-soluble fertilizer granules of different sizes to meet specific needs.

What is the hardness of the water soluble fertilizer granules produced by the new organic fertilizer granulation machine?

The hardness of the water soluble organic fertilizer granules produced by the New Organic Fertilizer Granulation Machine is usually between 5 y 8 on the Mohs hardness scale. This level of hardness ensures the mechanical resistance of the granules, allowing them to remain intact during transport and application without becoming dusty. At the same time, adequate hardness also ensures durability of particles in the soil and slow release of nutrients, which helps improve fertilizer efficiency.

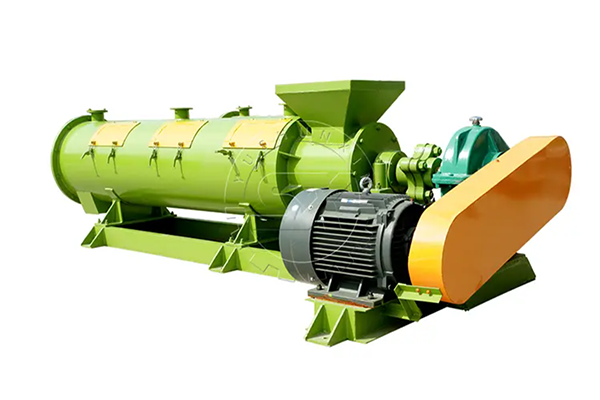

What are the advantages of the new organic fertilizer granulator?

High degree of automation. The New Organic Fertilizer Granulation Machine is equipped with PLC automatic control system, which can realize real-time monitoring and adjustment of the entire production process of water-soluble fertilizers. This high degree of automation reduces manual intervention and improves product stability and consistency in the production of water-soluble organic fertilizers..

High granulation rate. The qualified granulation rate of the new organic fertilizer granulation machine is as high as 97% and the water-soluble fertilizer granules produced are of high hardness.

Save energy. The new organic fertilizer granulator does not need to dry or crush raw materials before granulation. Can process spherical particles by directly mixing ingredients, saving a lot of energy.

Excellent environmental performance. The new granulator fully takes into account environmental protection requirements during the design and production process and adopts closed granulation. Reduces dust and residual gas emissions during the production process.

If you are also interested in other equipment such as water soluble fertilizer mixer, water soluble fertilizer crusher y material dryer. Don't hesitate to contact us. We have a professional team of engineers to make production plans for you!!