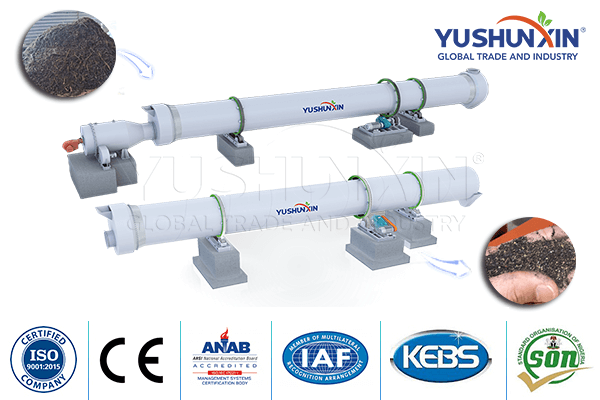

Rotary Drum Dryers

Ability: 1-20 t/h

dry moisture: <10 %

Precio: $10,000-$80,000

Drying method: Hot air drying

Application: Dust, granules, fertilizers, manure, sludge, pomace…

Description

Rotary drum dryer is generally used to dry soluble fertilizers and reduce moisture to a low level, lower than 10 %. This allows the fertilizer to be stored for a long time without sticking. To fully satisfy your needs, YUSHUNXIN designs various drying machines, both industrial and small scale (1-20 t/h). These machines help you process water-soluble fertilizers, such as NPK and organic, powder and granules, etc., with a budget of between $10 000 y $80 000. Besides, We have customized soluble fertilizer dryers and drying systems.

Can rotary drum dryer reduce the moisture content of soluble fertilizer by 10%?

Of course. A rotary drum dryer is a highly efficient industrial fertilizer drying system that can, in fact, reduce the moisture content of the soluble fertilizer to a 10%, and included a 5%. This is achieved thanks to its 300℃ hot air drying method combined with an innovative rotary design..

Hot air drying at 300℃ for rapid reduction of fertilizer moisture

Hot air at 300℃ for drying soluble fertilizer is generated by gas burner and hot air oven. Then, This is transferred to the rotary drum dryer.. The high temperature of the hot air is essential to quickly evaporate the moisture content in the soluble fertilizer.

Rotating drum design for better removal of water in fertilizer

On the one hand, rotary design ensures material is evenly exposed to hot air, which accelerates the drying process of soluble fertilizer. On the other hand, It also prevents possible agglomeration or adhesion of the fertilizer during drying, ensuring a constant final quality of the soluble fertilizer.

Can rotary drying equipment process 20 tons of soluble fertilizer?

Of course. To fully meet your soluble fertilizer production needs, both large and small scale, We have various models of drying equipment, with capabilities from 1 t/h up to 20 t/h.

- For soluble fertilizer plants 1 a 10 t/h, you can choose SXHG rotary drum dryers-0808, SXHG-1010, SXHG-1212, SXHG-1515, SXHG-1616 THE SXHG-1818.

| Model | Engine power (kW) | Inlet temperature | Rotation speed (rpm) | Ability (t/h) |

|---|---|---|---|---|

| SXHG-0808 | 5.5 | ≥300°C | 6 | 1-2 |

| SXHG-1010 | 7.5 | ≥300°C | 6 | 2-4 |

| SXHG-1212 | 7.5 | ≥300°C | 6 | 3-5 |

| SXHG-1515 | 11 | ≥300°C | 6 | 4-6 |

| SXHG-1616 | 15 | ≥300°C | 6 | 6-8 |

| SXHG-1818 | 22 | ≥300°C | 6 | 7-12 |

- For drying in production of soluble fertilizers 10 a 20 t/h, We also have the SXHG-2020 models, SXHG-2222 THE SXHG-2424.

| Model | Engine power (kW) | Inlet temperature | Rotation speed (rpm) | Ability (t/h) |

|---|---|---|---|---|

| SXHG-2020 | 37 | ≥300°C | 5.8 | 8-15 |

| SXHG-2222 | 37 | ≥300°C | 5.5 | 8-16 |

| SXHG-2424 | 45 | ≥300°C | 5.2 | 15-20 |

What is the price of a rotary drum dryer?

The price of a rotary drum dryer for soluble fertilizers depends on several factors. Generally, the price of a rotary drum dryer 1 a 20 t/h oscilla between $20,000 y $100,000.

- First of all, The price is closely related to the model or drying capacity. For example, a lower budget is needed to purchase a SXHG-1616 drum dryer than the SXHG-2424, since the latter can dry out 14 a 20 tons of soluble fertilizers per hour, considerably more than that of SXHG-1616.

- On the other hand, If you need a customized dryer for soluble fertilizer processing, generally involves additional expense, as a fertilizer dryer with fast heating, a layer of insulation, material, etc.

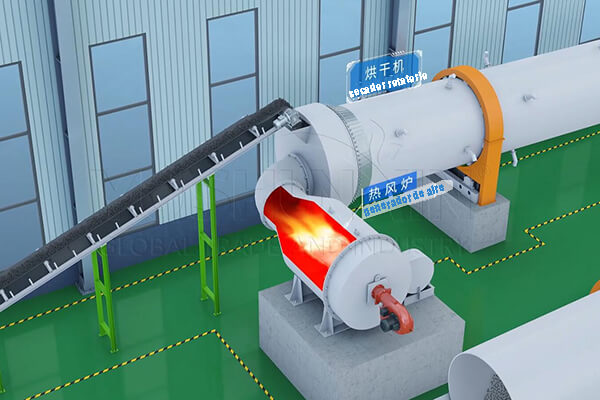

How to offer heat for industrial drying of soluble fertilizer?

As mentioned above, YUSHUNXIN soluble fertilizer dryer adopts hot air to 300 ℃. So, How is hot air supplied for industrial drying of soluble fertilizer effectively?? Generally, are required 3 machines: gas burners, hot air ovens and industrial fans.

gas burner

The gas burner is a device that generates fire to heat the air.. It is widely used in drying soluble fertilizer due to its clean combustion, stable flame and ability to reach high temperatures quickly. Here, YUSHUNXIN can offer gas burners, of oil, biomass, etc., according to your needs.

hot air oven

Hot air ovens provide a space to generate hot air for industrial drying of water-soluble fertilizers. There are hot air ovens that are used after gas burners and also after diesel burners respectively.. These ovens create a constant flow of hot air, which then goes to the drying drum.

Industrial fans

Finally, The fans play a supporting role by circulating and controlling the distribution of hot air within the dryer. Ensure uniform heat transfer, prevent overheating and improve drying efficiency in the production of soluble fertilizers.

On the whole, These systems form an integrated heat supply solution that balances cost, energy efficiency and product quality in drying soluble fertilizers.

What material can the soluble fertilizer dryer process?

Can the soluble fertilizer drying machine be used to dry materials with a 70% of humidity? Does it serve both for the manufacture of organic water-soluble fertilizer and for the compound? In powder or granules? Here you have all the answers.

Recommended drying for materials with less than 50% of humidity

It is advisable to purchase the rotary dryer to process materials with moisture content less than 50%. Because? There are two reasons.

On the one hand, energy consumption for fertilizer drying becomes extremely high, which significantly increases costs.

On the other hand, wet material tends to stick to the inner wall of the drum, causing operational difficulties and reducing drying efficiency.

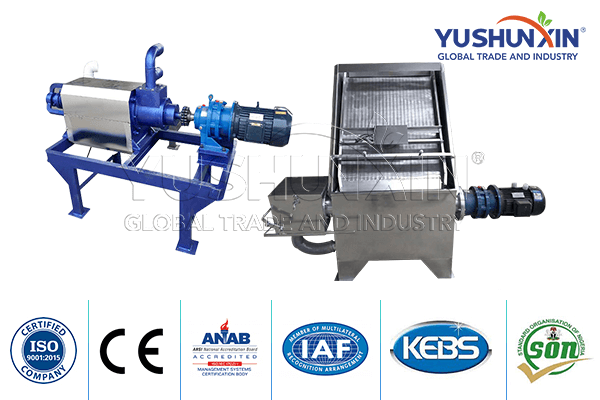

Therefore, during the manufacturing of organic soluble fertilizer, we first process the manure with a dehydrator.

Both for the manufacture of soluble organic and compound fertilizer

So, What kind of water soluble fertilizer manufacturing can the rotary dryer work for?? Both for the organic fertilizer production as for the compound fertilizer production. That is to say, you can use it to dry NPK water soluble fertilizers, cow dung, chicken manure, trace elements, etc.

Can you dry powder and granule fertilizers?

The answer is yes. Whether your goal is to dry powdered fertilizer or stabilize finished granules, rotary drying machine ensures effective moisture reduction quickly.

In addition to fertilizer manufacturing, drum dryer is also an ideal choice for other industries. For example, drying fruit waste, sludge drying…

Besides, There are also many other water soluble fertilizer making machines waiting for you. Como, For example, he granulator, he composting equipment, the crusher, the mixer, the bagging machine, etc. Come see them now!