Soluble fertilizer granulation technology 10 t/h

Product: Gránulos

Processing capacity: 10t/h

Precio: $360.000

Teams: Trituration, granulation, drying, refrigeration, packing, etc.

Description

Water-soluble fertilizer granulation technology is the process of converting water-soluble fertilizers into water soluble granular fertilizers through granulation technology. According to different production processes, The production technology of water-soluble organic fertilizers is divided into dry granulation technology and wet granulation technology. Para tecnología de granulación de fertilizantes solubles en agua en húmedo. You can choose new organic fertilizer granulators, mixing drum compound granulators, disc granulators and drum granulators. For dry water-soluble fertilizer granulation technology. Puede elegir entre un granulador por extrusión de doble rodillo y un granulador de matriz plana.

Which granulator can be used for wet water soluble fertilizer granulation technology?

Para la tecnología de granulación de fertilizantes solubles en agua en húmedo, you can choose a new organic fertilizer granulator, a stirring drum compound granulator, a disc granulator and a drum granulator.

New organic fertilizer granulator

If you want to produce water-soluble organic fertilizer granules with high hardness and high granulation rate, you can choose a new organic fertilizer granulator. The shape of the water-soluble fertilizer particles produced by our new organic fertilizer granulator is spherical.. The particle size is generally between 2 y 5 mm and the granulation rate is >90 %. The diameter of water-soluble fertilizer particles can be adjusted. appropriately according to the amount of mixed materials and the rotation speed of the screw.

Stirring Drum Composite Granulator

If you want a granulator that produces water-soluble organic fertilizer granules with beautiful and durable shapes, You can choose the rotary drum compound granulator with agitating teeth. Our stirring teeth rotary drum compound granulator uses a combination of stirring teeth wet granulation technology and rotary drum wet granulation technology.. The combination of these two granulation methods makes the water-soluble fertilizer granules have a higher balling rate and more beautiful granules.. It is a molding machine that can convert materials into specific shapes.

Disc granulator

If you want a low price and small size water soluble fertilizer granulator, you can choose a disc granulator. The surface area of a disc granulator is from 0,4 a 12 m2. The price of a disc granulator to produce water soluble organic fertilizers generally varies from 3000 $ a 7500 $. Varies depending on model, the material and purpose. For example, a disc granulator with model SXYZ-2800 is more expensive than a disc granulator with model SXYZ-2000.

drum granulator

If you want a water soluble fertilizer granulator with strong corrosion resistance and high performance, you can choose a granulador de tambor. The drum granulator is made of carbon steel outside and lined with special rubber sheets, which greatly improves the corrosion resistance of water soluble compound fertilizers to drum granulator. Besides, el granulador de tambor YUSHUNXIN can produce water-soluble organic fertilizer or water-soluble compound fertilizer with a maximum production of 30 tons/hour

Is there a more favorable granulator?

The answer is yes. If you want a more affordable water soluble fertilizer granulator. Dry water-soluble fertilizer granulation technology can be used. Dry granulation technology does not require drying or cooling equipment. It can save the production cost of water-soluble organic fertilizers.

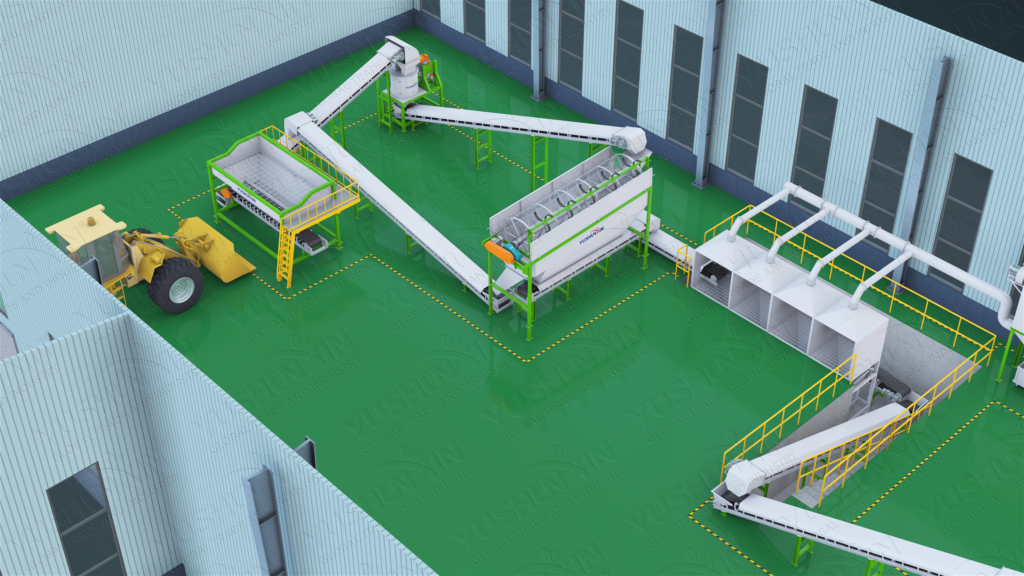

Dry water-soluble fertilizer granulation technology is a water-soluble fertilizer granulation method using drum dry pressing technology.. Mainly used to compress powder materials with moisture content ≤5% into flakes or blocks. Then it goes through processes such as crushing, granulation and screening. Convert flake and block materials into compliant water-soluble fertilizer granular materials. . usage requirements. Water-soluble fertilizer dry granulation technology can use double roller extrusion granulator and flat die granulator.

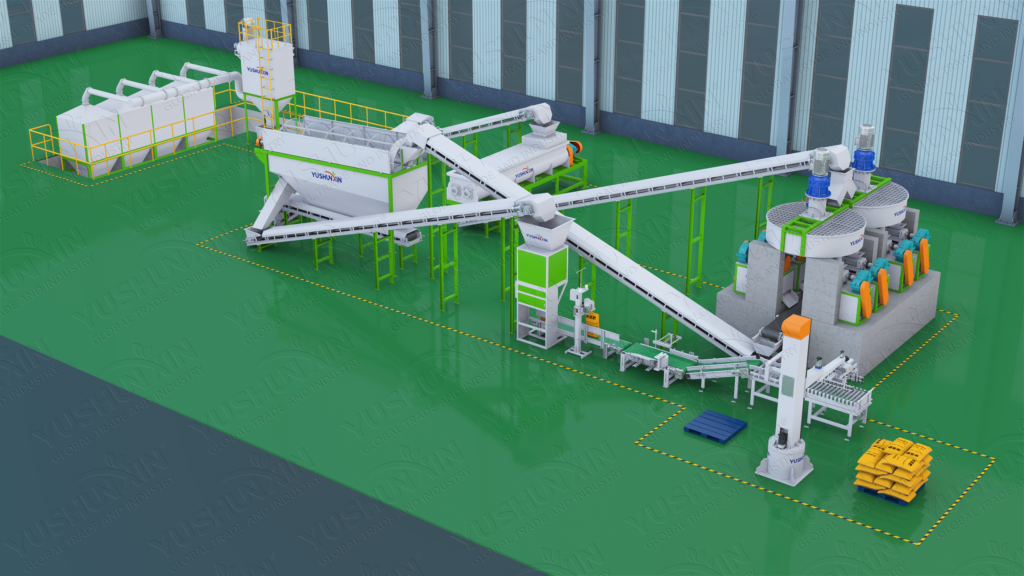

Is there a water soluble soluble fertilizer granulation production line of 10 t/h?

If you want a water soluble fertilizer granulation production line from 10 t/h, can choose 6 double roller extrusion granulators of 1,5 t/h. Working at the same time, puede producir 10 tons of water-soluble organic fertilizer per hour. The main process flow of water soluble organic fertilizer granulation production line includes dosing, mix, granulation and packaging.

Dosage. Various raw materials and auxiliary materials are dosed in a certain proportion to ensure that the water-soluble organic fertilizer produced meets the requirements.

Mezcla. The ingredients are mixed thoroughly by mixer to ensure that the raw materials are mixed evenly.

Granulation. The mixed materials are processed into water-soluble granular fertilizers using dry granulation technology., as a double roller extrusion granulator.

Packing. Cooled water soluble fertilizer granules are automatically weighed and packaged.