The materials for water-soluble liquid fertilizer equipment are generally made of stainless steel.. To ensure it can operate efficiently, durable and safe. At the same time, meets chemical stability requirements and hygiene standards during the production process. Materials for liquid fertilizer equipment YUSHUNX specifically include stainless steel 304 y 316L.

Why should water-soluble liquid fertilizer production equipment be made of stainless steel??

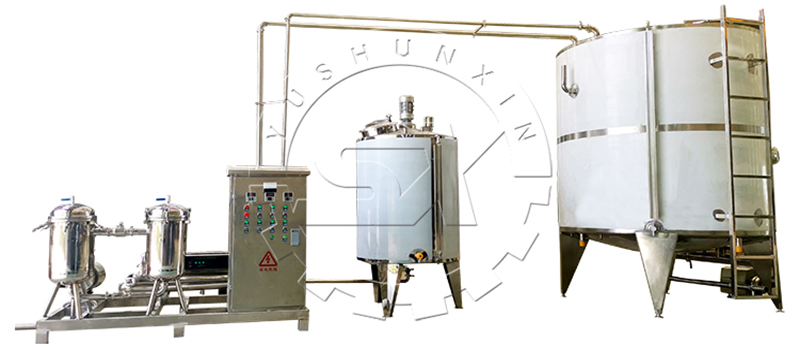

Liquid fertilizer equipment

The main reasons for using stainless steel in liquid fertilizer equipment materials are its corrosion resistance and durability.. Besides, Stainless steel has good corrosion resistance and can resist equipment corrosion caused by chemical components of water-soluble fertilizers.. Water-soluble fertilizers are chemically corrosive. The use of stainless steel not only ensures that the equipment will not be damaged by corrosion during prolonged use, but also prolongs the life of the equipment. Besides, The durability of stainless steel is one of the reasons why it is widely used. There is an oxide film on the surface of stainless steel. Can isolate corrosive media. It also protects the interior of the device from damage. On the contrary, Carbon steel rusts easily and is not suitable for use in equipment production of water soluble fertilizers. In summary, The corrosion resistance and durability of stainless steel make it an ideal choice for equipment production of water-soluble liquid fertilizers.

How much does stainless steel water soluble fertilizer production equipment cost?

Stainless Steel Aqueous Liquid Fertilizer Production Equipment. Costs vary depending on device type and configuration. Commonly used water-based liquid fertilizer production lines include feeding equipment. Filtration equipment and sterilization equipment. Equipment such as fermentation equipment, reaction teams, finished product storage equipment and packaging equipment.

Liquid fertilizer production line.

Take NPK liquid fertilizer production line as an example., one of the three lines most popular production. Equipment to be equipped includes feeders, filters, sterilizers, fermentation machines, reaction vessels, tanques de almacenamiento de productos terminados y máquinas llenadoras. All production equipment is made of stainless steel. The total investment for an NPK liquid fertilizer production line generally ranges between $30 000 y $250 000.

How to make water-soluble liquid fertilizer?

The process of making water-soluble liquid organic fertilizer includes the following steps:

Preparation and filtration of raw materials: put the prepared water-soluble liquid fertilizer raw materials into the reaction vessel from the feeding port. Then filter to remove impurities.. Ensure the quality of the original solution.

Automatic lot: Automatic batching according to production needs. Complete the work of automatic dosing system.

Reactor reaction: Water-soluble liquid fertilizer raw materials are heated, cooled and stirred in the reactor. Forms water-soluble liquid fertilizer.

Emulsification treatment: Emulsify the liquid in the reactor to achieve a uniform liquid, free of particles and without precipitation.

Liquid storage and filling: put the processed liquid into the liquid storage tank for later use and then fill it. There are production lines for vat filling and small bottle filling, choose according to your needs. La máquina envasadora used for water soluble liquid fertilizers is a filling machine.