Peru, as one of the 12 largest mineral producing countries in the world, has rich mineral resources. Phosphate rock fertilizer is one of the fertilizers with the highest phosphorus content on the market.. It is mainly used to promote the growth and development of crop roots and promote the ripening of fruits and seeds.. Therefore, Phosphate rock fertilizer production is very popular among local fertilizer manufacturers. He 17 September 2023, A customer from Peru asked about the Phosphorus rock as phosphate fertilizer. Specific details are as follows:

Main parameters

Country: Peru

Ability: 10t/h

Material: phosphate rock

Requirements: converted into water-soluble powder fertilizer.

Can your equipment produce rock phosphate fertilizer?

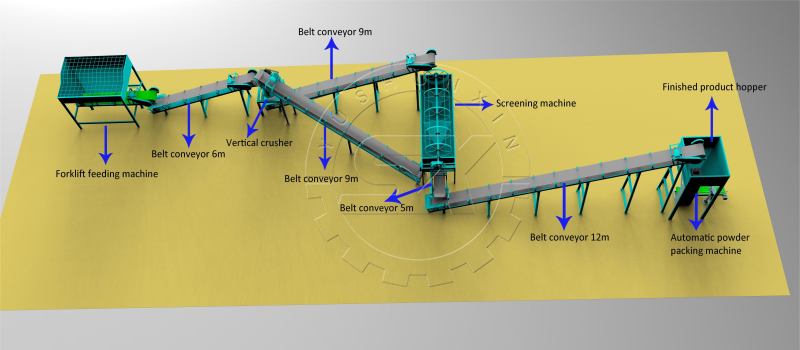

Peruvian clients want to use phosphate rock as water-soluble phosphate rock fertilizer. Our water soluble solid fertilizer equipment It is an excellent option to process them and convert them into fertilizer. Because our fertilization equipment is highly adaptable. It can be used to produce water-soluble rock phosphate fertilizers of different concentrations and scales.. The equipment used to produce water-soluble phosphate rock fertilizer powder mainly includes crushers, dryers, packaging machines and conveyor belts.

Which crusher do you recommend for the production of water soluble fertilizer powder from phosphate rock??

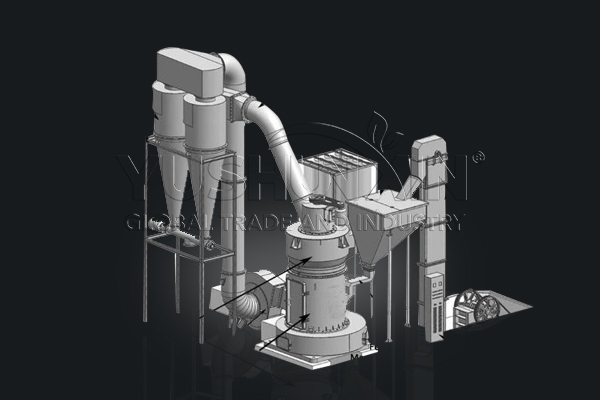

This Peruvian client wants to convert phosphate rock in water soluble powder fertilizer, So you want to know which crusher is best for your manufacturing needs and we recommend one. crusher which is mainly used for phosphate rock. Molino raymond。 The Raymond mill is mainly based on rotation and centrifugal force of grinding roller device for crushing phosphate rock. The Raymond mill does not have high requirements on the size of the feed particles and is completely suitable for large materials.. The discharged ultrafine powder with an average particle size of 6,5 μm can be discharged at the same time, and the phosphate rock fertilizer produced meets industry standards. Besides,The Raymond Mill SX has a production capacity of 1 a 20 tons per hour. Can fully satisfy the demand of 10t/h of Peruvian customers.

What is the production process of powdered rock phosphate water soluble fertilizer?

The basic process is: first, the ore is ground and the crushed phosphate rock is ground to a fine powder through a Raymond mill. Next, the phosphate rock fertilizer is dried and the ground phosphate rock fertilizer is sent to the drum dryer for dehumidification to obtain a standard compound phosphate rock fertilizer. The last step is packaging. The dry rock phosphate fertilizer is weighed and packaged in a packaging machine automatic. The entire production process is transported by belts.