9 March 2025. We received an email from a customer in Malaysia. He told us that he wanted to build a water soluble organic fertilizer production line at low cost. The details are as follows:

What kind of metering machine is used with water soluble organic fertilizer production line?

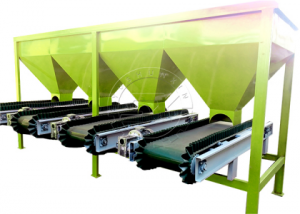

As to dosing machines, We have equipped you with an automatic four-container dynamic dosing machine. You can use the dosing machine to add trace elements to raw materials. Continuously discharge materials into four containers and can automatically adjust the dosing ratio according to different elements.

Which granulator is suitable for this organic fertilizer production line?

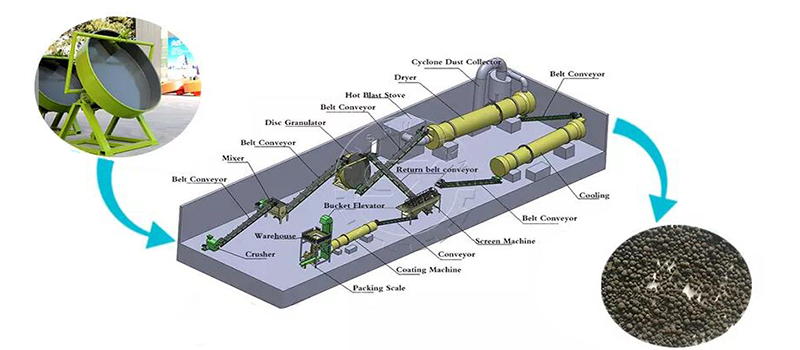

We configure a disc granulator for this organic fertilizer preparation line. The first thing is that the disc granulator has a low price. The price of the disc granulator is between 3000$ y 7000$, which is lower than other water soluble fertilizer granulators and can save cost. Meet your low-cost needs. The second is the high granulation rate. The granulation disc of the disc granulator adopts an arc structure as a whole and the granulation rate can reach exceed the 93 %. Finally, has specific scraper settings. The disc granulator has a scraper adjustment to prevent material from sticking and building up on the disc granulator, which can reduce material waste.

What is the price of the whole water soluble organic fertilizer preparation line?

This water soluble organic fertilizer production line is equipped with equipment such as automatic dynamic dosing machine, SXPJ-2000 disc granulator, rotary dryer, screening machine and automatic packaging machine. The production line uses a link device PLC, the price is $ 187500.

What is the delivery time of water soluble organic fertilizer preparation line?

Delivery time of water soluble organic fertilizer preparation line YUSHUNXIN is generally subject to multiple factors, including equipment customization, the organization of production and logistical transportation. In general terms, The entire process from contract signing to final delivery may take between 2 y 4 months.

First, we need to design and customize according to customer's specific requirements, a process that can take several weeks or a month. This is followed by the production and assembly of the device, a step that typically takes between four and eight weeks. The final step is to test and debug the equipment to ensure that all systems work normally. Coordination and organization of time is also required during the transportation and installation process..